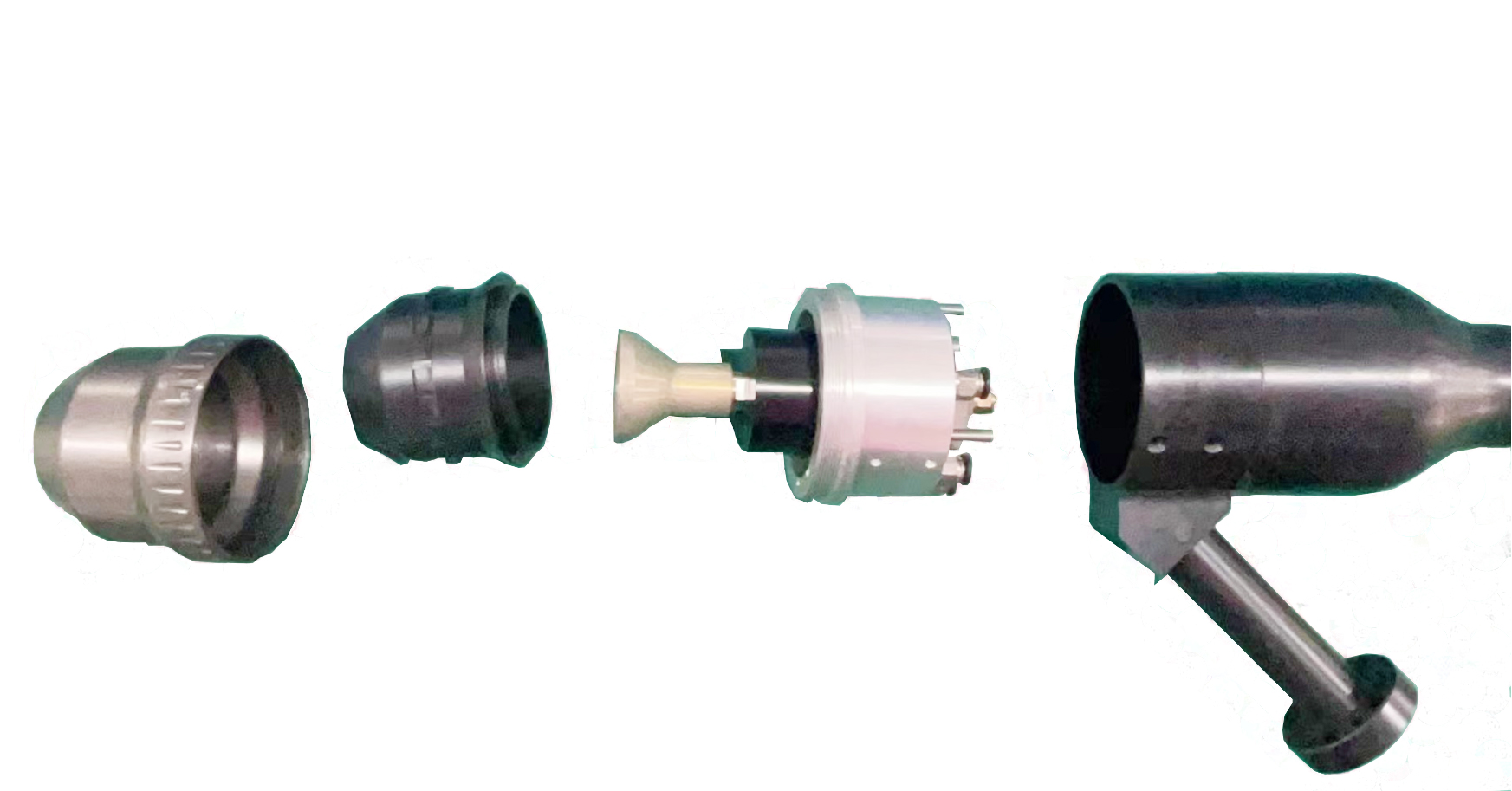

1、HDA-60 high speed pneumatic motor

2、(MAX):DC -80KV,Adjustable

3、H.V Power pack:External

4、rotating speed(unload):80000rpm MAX.

5、driving method:air bearing motor

6、weight:2.5KG(single bell gun without any cable)

Air pressure:

1、Turbo motor:550ml/min——42000rpm(400l/min)

2、Air bearing:60l/min(normal)

3、Forming air:170—540l/min(normal)

4、Air brake:100l/min(normal)

Parameter:

1、Paint pressure:0.69MPA max

2、Paint flow:25-600cc./min

3、Bell cup:30mm/50mm

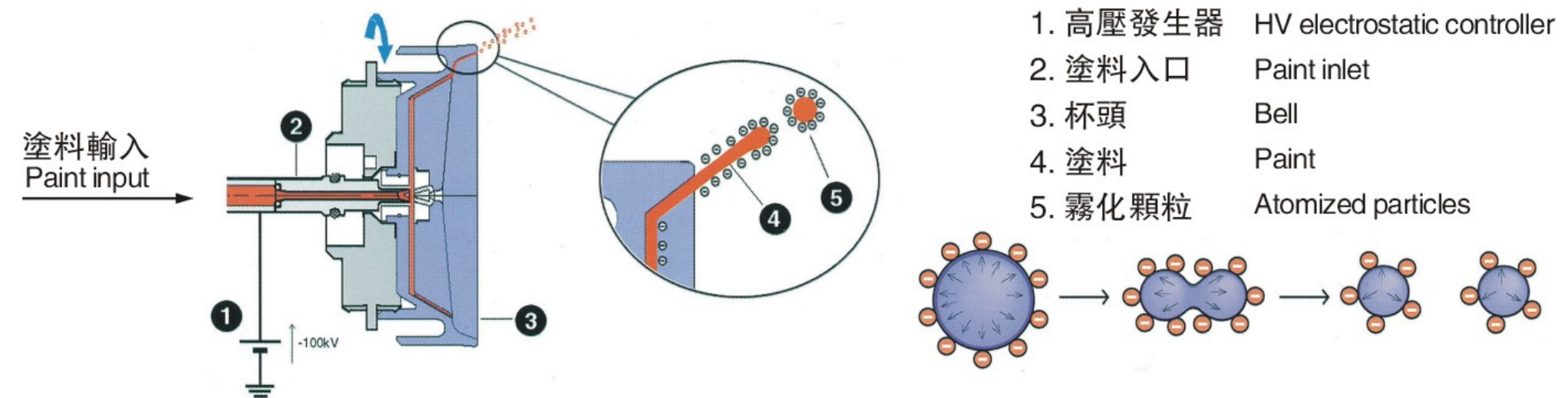

Rotating atomizing bell cup

The principle of electrostatic Rotating atomizing bell cup is based on electrostatic force, which is the interaction force generated by substances at different potentials. When there is a potential difference between two charged bodies, a static electric force is generated, causing the charged body to move relative to each other. In an Rotating atomizing bell cup , the material is guided into the rotating cylinder by a high-voltage power supply. Due to the friction between the inner wall of the rotating cylinder and the surface of the material, the material is charged and generates centrifugal force during rotation; At the same time, due to the different electrical conductivity between materials, an electric field and potential difference are generated, resulting in the generation of electrostatic force. During the rotation process, materials will separate due to different factors such as quality, charge, and electrical properties, thus achieving the separation effect of Rotating atomizing bell cup.

The principle of electrostatic Rotating atomizing bell cup is based on electrostatic force, which is the interaction force generated by substances at different potentials. When there is a potential difference between two charged bodies, a static electric force is generated, causing the charged body to move relative to each other. In an Rotating atomizing bell cup , the material is guided into the rotating cylinder by a high-voltage power supply. Due to the friction between the inner wall of the rotating cylinder and the surface of the material, the material is charged and generates centrifugal force during rotation; At the same time, due to the different electrical conductivity between materials, an electric field and potential difference are generated, resulting in the generation of electrostatic force. During the rotation process, materials will separate due to different factors such as quality, charge, and electrical properties, thus achieving the separation effect of Rotating atomizing bell cup.

Connections:

Applications:

Hardware, furniture, crib, luggage accessories, sports equipment, new energy accessories, motorcycles, automotive parts, glass bottle, household appliances,etc

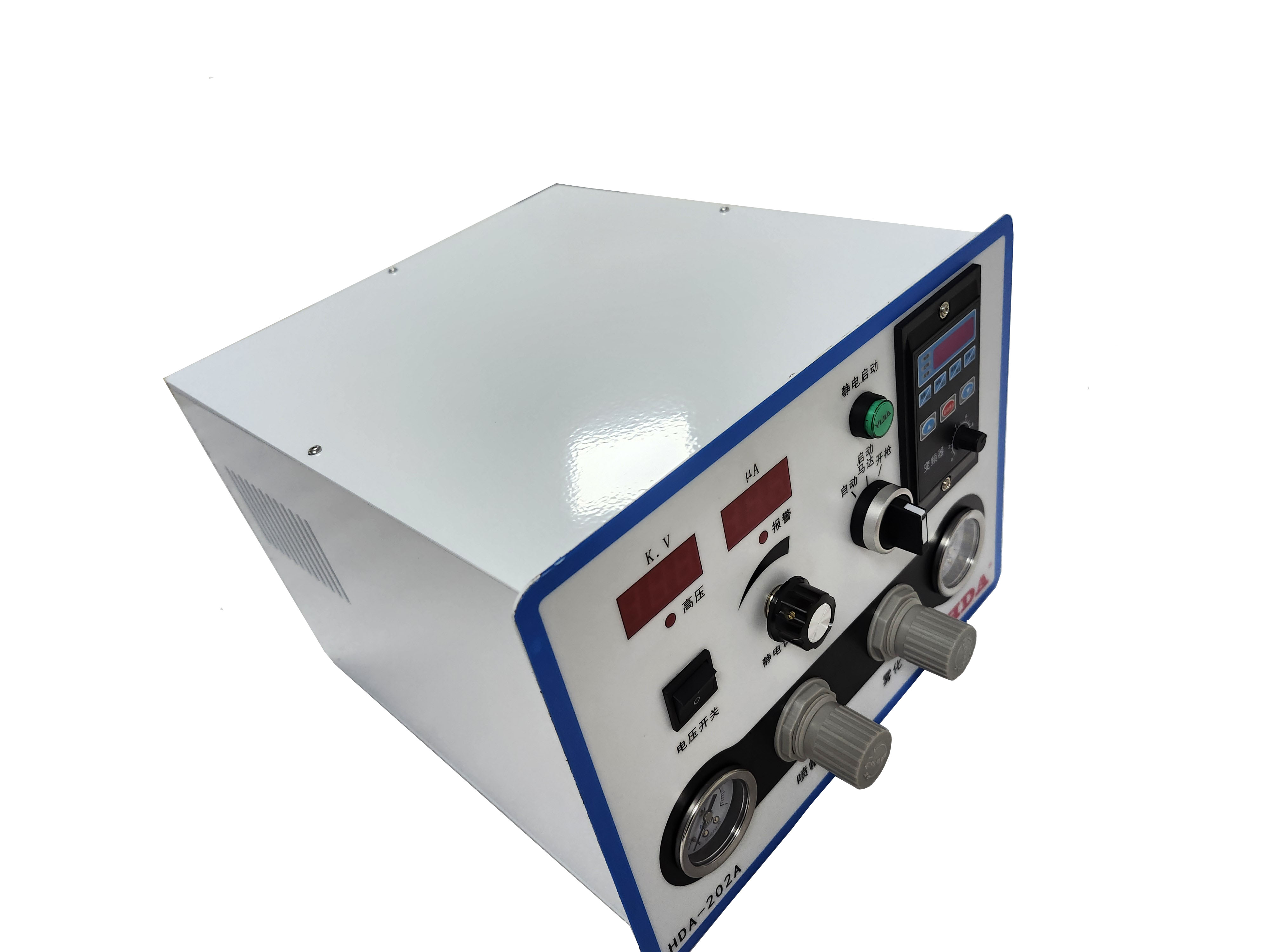

HDA-202 smart control:

1、HDA-202 smart control cabinet

Electrostatic spray gun atomization, air adjustment of spray amplitude unit

1) Electrostatic spray gun coating switch gun control

3) Control of spray gun paint discharge adjustment

4) Static high-voltage switch adjustment

5) External control signal can be connected

high voltage: DC-80KV

high voltage adjustment: 15KV- 18KV unsection

high voltage switch: Automatic & Manual,

supply voltage: AC110V-240V 50/60Hz

;

Intro

Intro Description

Description

Intro

Intro Description

Description Related Products

Related Products