How to implement liquid electrostatic rotary bell spray gun that can also be sprayed with a robotic arm?

2026.02.02

How to implement liquid electrostatic rotary bell spray gun that can also be sprayed with a robotic arm?

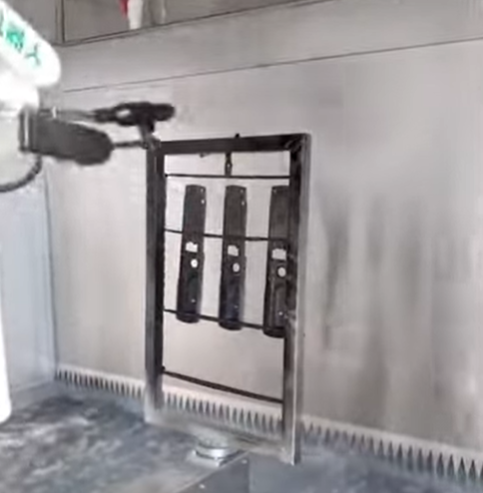

The combination of liquid electrostatic rotary bell spray gun and robotic arm (industrial robot) is the mainstream solution in modern automated painting systems, which can achieve high-precision, high-efficiency, and high consistency spraying operations. This integration method is widely used in mass production lines in industries such as automobiles, home appliances, and furniture.

implementation method:

The robotic arm serves as a motion platform: the electrostatic rotary bell spray gun (also known as the rotary bell electrostatic spray gun) is firmly installed on the end effector of the industrial robot. Robots are responsible for accurately controlling the movement trajectory, speed, and posture of spray guns in three-dimensional space, replacing traditional fixed reciprocating machines or manual operations.

Integrated high-voltage electrostatic system:

The rotary bell spray gun needs to be connected to a high-voltage electrostatic generator (usually providing negative high voltage of DC20-80kV). The high-voltage power supply is connected to the robot body through a specialized cable management system (such as a drag chain or winding reel), ensuring that the high-voltage cable can safely and reliably transmit electrical energy during robot movement, avoiding entanglement or wear.

Synchronous control system:

The surface spraying control system (PLC or dedicated controller) of the robot interacts and links with the control unit of the electrostatic spraying system. The system will precisely control based on the shape, position, and spraying process requirements of the workpiece

Robot motion path: Ensure a constant distance between the spray gun and the workpiece surface (usually 25-35cm).

Rotating cup speed: Adjust centrifugal force to control the particle size and spray width shape of paint atomization.

Paint flow rate:

The paint output per unit time is controlled by a precision metering pump.

High voltage: dynamically adjust the voltage according to the distance between the spray gun and the workpiece to ensure spraying effect and safety.

Environment and safety protection: The system will integrate safety functions, such as automatically cutting off the high-voltage power supply when the robot detects abnormal collisions or when the spray gun is too close to the workpiece, to prevent the risk of electric shock or sparks. Meanwhile, the spraying area is usually equipped with ventilation and paint mist collection systems to ensure environmental safety.

Advantage

High flexibility: Robots can easily adapt to complex and irregularly shaped workpieces, achieving fully automated spraying without the need to create dedicated fixed spraying equipment for each new workpiece.

High precision and consistency: The robot has high repeatability in motion, ensuring that the spraying thickness and quality of each workpiece are highly consistent.

High efficiency: It can work continuously 24 hours a day, and with the cooperation of the conveyor chain, it can achieve the automation spraying rhythm of the production line.Material saving: Combined with electrostatic rotating bell spry technology, the utilization rate of coatings can be increased to over 80%, significantly reducing material costs and VOC emissions

Previous:Is already the first one

Next:How to solve the insulation problem of electrostatic spray gun for solvent based paint spray?

Related Information

- How to implement liquid electrostatic rotary bell spray gun that can also be spr

- How to solve the insulation problem of electrostatic spray gun for solvent based

- What functions HDA-605 smart set of electrostatic rotating bell spray equipment?

- industrial Surface spray solution liquid electrostatic spraying

- HDA rotating bell spray system for the user inspection and learning the installa

- HDA spray gun three-way valve HCV 13

- alumium lin spraying

- HDA -114 electrostatic spray gun

- The HDA electrostatic spray equipment is most popular equipment in the interlak

- How is HDA-1020 manual electrostatic spray gun works?

- Why electrostatic spray gun not change model so offen?

- Electrostatic spray system CE certificate

- High atomization manual electrostatic paint spray gun|hdaspraygun

- New energy vehicles Automotive spare parts automatic spraying|hdaspraygun

- Aluminum surface spraying methods

- What industries are electrostatic spray guns used for?

- Spraying process of glass bottles

- Electrostatic spray Glass packing bottle spray equipment

- Automatic spraying equipment and coating technology

- China best electrostatic spray equipment manufacture

BACK

BACK HDA HOME

HDA HOME Navbar

Navbar