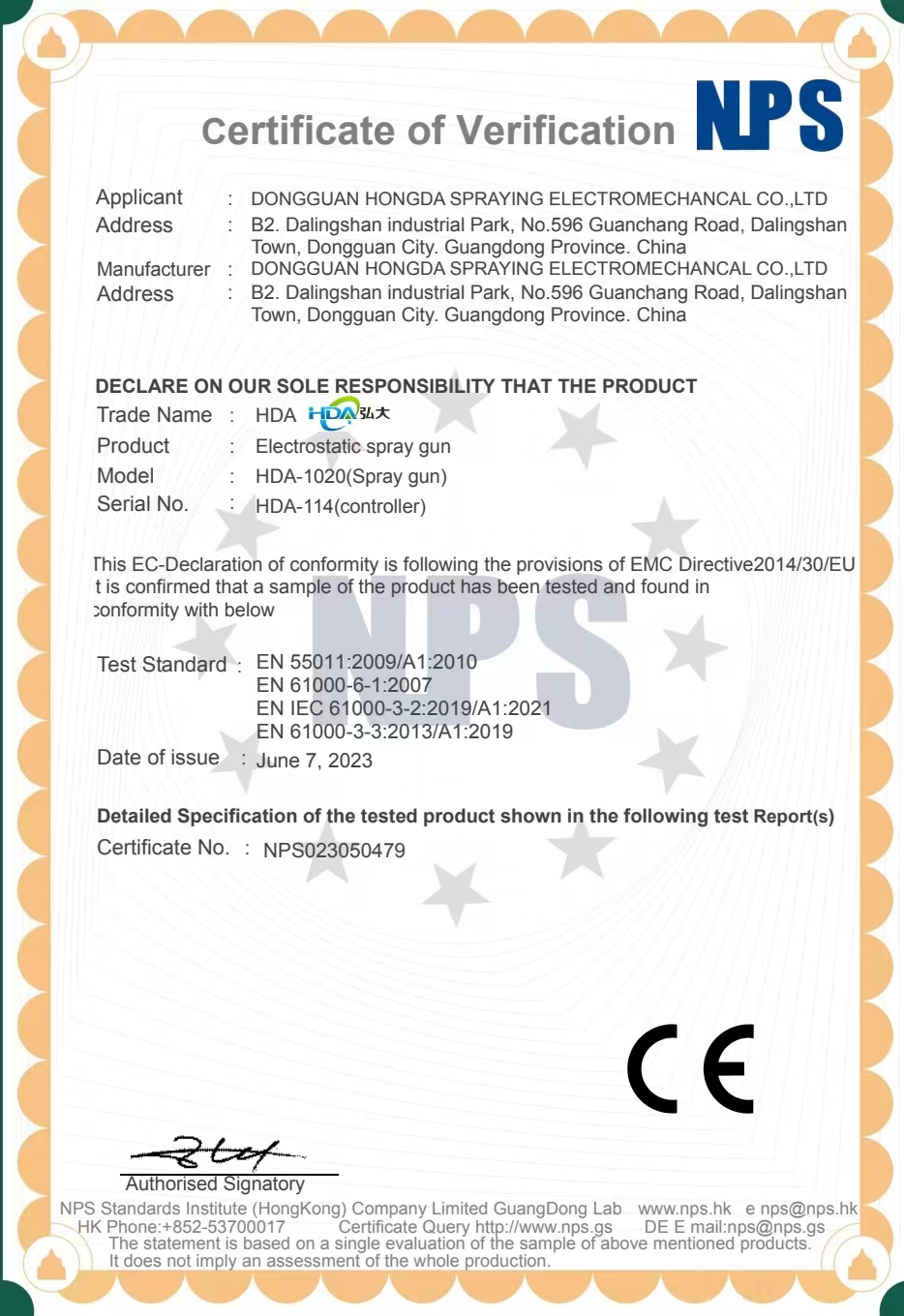

Electrostatic spray system CE certificate

2023.06.15

what is the difference between CE certificate 2014/30/EU standard and 2014/35/EU standard

Low Voltage Directive (LVD)

The low voltage directive (LVD) (2014/35/EU) ensures that electrical equipment within certain voltage limits provides a high level of protection for European citizens, and benefits fully from the single market. It has been applicable since 20 April 2016.

About the low voltage directive (LVD)

The low voltage directive (LVD) covers health and safety risks on electrical equipment operating with an input or output voltage of between

50 and 1000 V for alternating current

75 and 1500 V for direct current

It applies to a wide range of electrical equipment for both consumer and professional usage, such as

household appliances

cables

power supply units

laser equipment

certain components, e.g. fuses

EU legislation in the electrical sector is important to ensure that health and safety requirements are the same across Europe for products placed on the market.

EMC Directive 2014/30/EU

The EMC Directive (2014/30/EU) regulates electromagnetic interference of electrical and electronic equipment. Have you ever heard a buzzing noise on your audio speakers when you hold a phone or electronic device next to it? What you hear is electromagnetic interference.

‘Electromagnetic compatibility (EMC) is the ability of electrical equipment and systems to function acceptably in their electromagnetic environment, by limiting the unintentional generation, propagation, and reception of electromagnetic energy which may cause unwanted effects such as electromagnetic interference (EMI) or even physical damage in operational equipment. The goal of EMC is the correct operation of different equipment in a common electromagnetic environment. It is also the name given to the associated branch of electrical engineering’.

The EMC Directive (2014/30/EU) aims to ensure that any electrical and electronic equipment minimizes the emission of electromagnetic interference that may influence other equipment. The directive also requires equipment to be able to resist the disturbance of other equipment.

In order to comply with the EMC Directive manufacturers must:

Design the equipment to comply with the electromagnetic emission and immunity requirements;

document test results and calculations that provide evidence for EMC compliance;

apply the labeling and marking requirements.

What does ‘EMC’ mean?

‘EMC’ stands for ‘electromagnetic compatibility. This refers to the ability of an electrical or electronic device to function with limited emission of electromagnetic interference and with limited susceptibility to these disturbances

Which products need to comply with the EMC Directive?

Products need to comply with Directive 2014/30/EU if they are EMC relevant, and if they are intended to be made available in one of the countries requiring the CE marking. The directive states that it applies to ‘products liable to generate electromagnetic disturbance, or the performance of which is liable to be affected by such disturbance, and to fixed installations This rather cryptical description means that the directive typically applies to products that contain electronics or active electrical components. This is regardless of whether these are mains-powered or battery-powered products.

The HDA-1020 electrostatic spray gun’s to meet the CE?

HAD-1020 High pressure air manual electrostatic liquid paint spray gun

High efficiency – save paint - environmental protection - low pressure atomization

High efficiency coating and outstanding operability

The new design is lighter, more flexible, more suitable for long time spray use

• excellent paint effect, more efficient paint

• contribution to environmental improvement and VOC mitigation! *VOC: volatile

High security

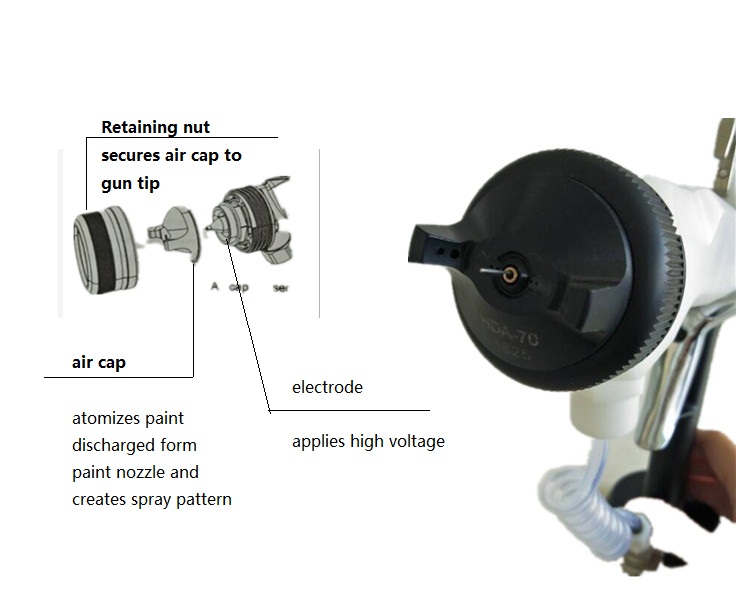

Because the built-in high voltage generator is inside the gun body,

So high security has been achieved.

Excellent machining

Equipped with excellent micronized HDA-60 nozzle,

Advanced coating effect can be achieved.

High coating efficiency

HDA-70 nozzles with excellent direct penetration and far surface arrival,

High coating efficiency can be achieved.

Seeking the most convenient use

Because it's a resin body and lightweight,

1020 liquid electrostatic spray gun handle just hold in hand, so long working hours do not feel tired.

Various adjustment and adjustment devices

As the regulator, hongda electrostatic spray gun can be easily adjusted to discharge quantity and paint spraying range.

HONGDA HAD-1020 Manual electrostatic spray gun date:

|

Use paint |

All conductive coatings / general coatings / metal paints |

|

|

Model |

HDA-1020 |

|

|

Voltage Max |

DC-60KV |

|

|

Hydraulic pressure |

Common |

0-0.3MPa |

|

Max |

0.6 MPa |

|

|

Air pressure |

Common |

0.05-0.4 MPa |

|

Max |

0.6 MPa |

|

|

Air consumption |

350N1/min(ANR) |

|

|

Air inlet |

Screw diameter PF1/4 |

|

|

Paint entrance |

Screw diameter PF1/4 |

|

|

Full length (HDA-70) |

231mm |

|

|

Length of connecting cable |

5m 8m (Max 30m) |

|

applications

1.Car coating:car body,car parts,larger container,plastic components

2.coating electric machinery coating:Switchboard, control panel, air conditioning machine, OA machinery, household electrical appliances

3. building materials, furniture: office machinery, steel furniture, doors and windows, walls, building materials Machinery coating:construction machinery,grinding machinery,production machinery.

4.others:hardware coating,painting and wooden products coating;

5.Glass bottle coating, glass perfume bottle coating, glass cosmetics bottle and glass wine bottle coating

DONGGUAN HONGDA SPRAYING ELECTROMECHANCAL CO.,LTD

Factory: B2. Dalingshan industrial Park, No.596 Guanchang Road, Dalingshan Town, Dongguan City. Guangdong Province. China

Contact person: Ms Croesus

Phone: 86 13622624429 (same as wechat)

E-mail:hda-sl01@hongdapt.com

Web:http://www.hdaspraygun.com

Previous:Why electrostatic spray gun not change model so offen?

Next:High atomization manual electrostatic paint spray gun|hdaspraygun

Related Information

- How to implement liquid electrostatic rotary bell spray gun that can also be spr

- How to solve the insulation problem of electrostatic spray gun for solvent based

- What functions HDA-605 smart set of electrostatic rotating bell spray equipment?

- industrial Surface spray solution liquid electrostatic spraying

- HDA rotating bell spray system for the user inspection and learning the installa

- HDA spray gun three-way valve HCV 13

- alumium lin spraying

- HDA -114 electrostatic spray gun

- The HDA electrostatic spray equipment is most popular equipment in the interlak

- How is HDA-1020 manual electrostatic spray gun works?

- Why electrostatic spray gun not change model so offen?

- Electrostatic spray system CE certificate

- High atomization manual electrostatic paint spray gun|hdaspraygun

- New energy vehicles Automotive spare parts automatic spraying|hdaspraygun

- Aluminum surface spraying methods

- What industries are electrostatic spray guns used for?

- Spraying process of glass bottles

- Electrostatic spray Glass packing bottle spray equipment

- Automatic spraying equipment and coating technology

- China best electrostatic spray equipment manufacture

BACK

BACK HDA HOME

HDA HOME Navbar

Navbar