HDA-90 Auto electrostatic spray gun

2026.01.21

The technical principle, structural design, and application advantages of the DA-90 automatic electrostatic spray gun, combined with innovative achievements in the field of electrostatic spraying, are analyzed for its key role in modern industrial spraying. Experience has shown that this device achieves efficient powder adsorption through a high-voltage electrostatic field, significantly improving spraying efficiency and coating quality, providing advanced solutions for the manufacturing industry.

As an advanced equipment in this field, the HDA-90 automatic electrostatic spray gun charges paint particles through a high-voltage electrostatic field and adsorbs them onto the surface of the workpiece, achieving efficient and uniform coating coverage.

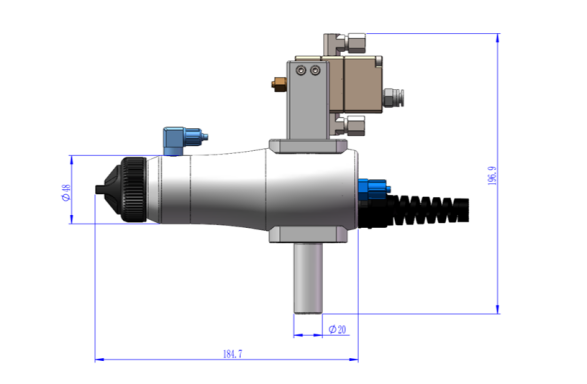

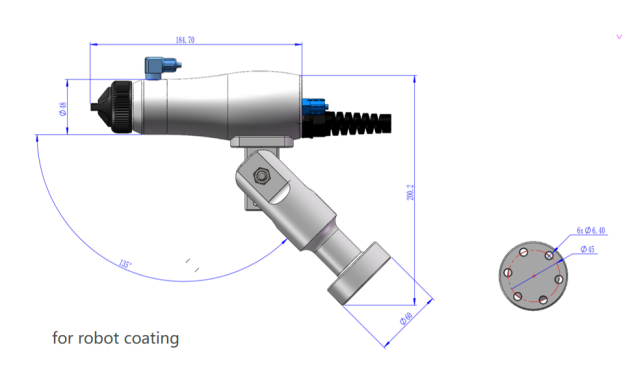

Specifications

|

Item |

Parameter |

remark |

|

|

Spray width |

350mm(Max) fan nozzle |

80mm (Max) round nozzle |

|

|

Paint flow rate |

600cc/min (Max) |

|

|

|

Spray width Air pressure |

0.1-0.3Mpa |

|

|

|

Atomization air pressure |

0.1-0.2 Mpa |

|

|

|

Tip of the nozzle |

1.2mm |

|

|

|

1.5mm |

|

|

|

|

1.8mm |

|

|

|

|

Paint control |

By the 3-way valve |

|

|

|

Air consumption |

100-250L/min |

150-200L/min |

|

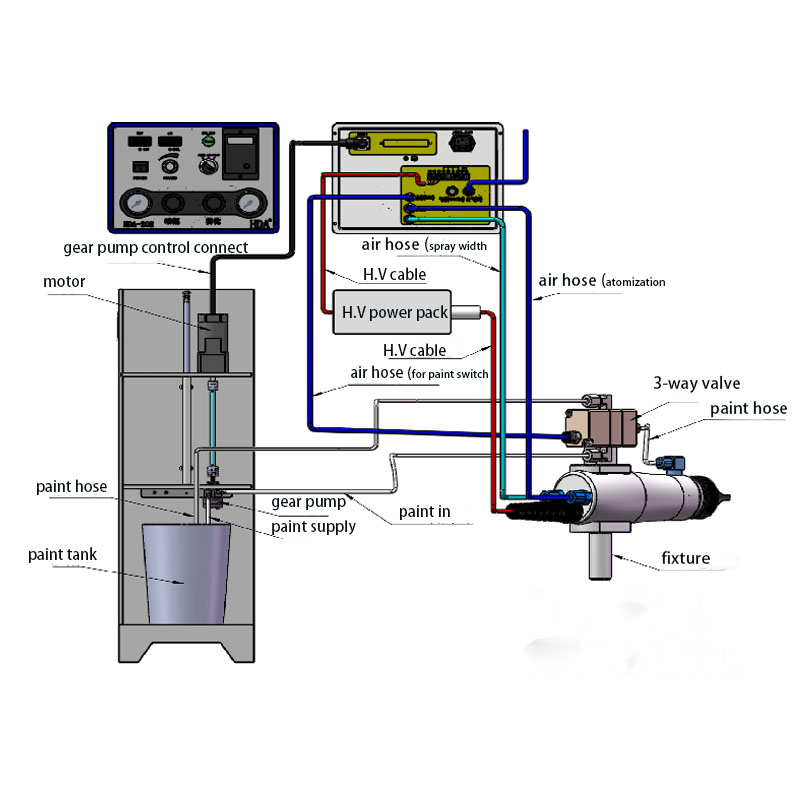

Connection Diagram

The HDA-90 automatic air electrostatic spray gun suitable for general industry has the advantages of simple structure, easy maintenance, strong penetrating force of paint fog, Multi application range of coatings, good performance of surface coating effect, and is the preferred product for large area paint spraying with strong penetrating force of coatings requirements.

How to use HDA-90 automatic electrostatic spray gun?

HDA-90 Automatic Electrostatic Spray Gun Usage Steps

Preparation work

Check connections: Ensure that all pipelines (air pipes, paint pipes, high-voltage cables) of the spray gun are securely connected and undamaged.

Grounding: Reliable connection of the ground wire of the electrostatic generator to the grounding terminal is crucial for safe operation.

Paint preparation: Insert the suction pipe of the oil pump into the prepared paint bucket and close the return pipe.

Parameter settings

Pressure regulation: Turn on the oil pump and adjust the pressure to approximately 3MPa. Then, open the air pressure valve of the electrostatic generator and adjust the total air pressure to 6MPa. During the spraying process, if you feel that the air pressure is too high, you can make slight adjustments by using the blue adjustment knob on the side of the spray gun.

Voltage regulation: Turn on the power of the electrostatic generator and adjust the output voltage to 60kV.

Spray operation

Start spraying: After confirming that the air pressure, voltage, and paint supply are normal, pull the trigger of the spray gun and start spraying.

Maintain distance: According to the process requirements, maintain a spraying distance of about 300mm between the spray gun and the surface of the workpiece.

Uniform movement: Move the spray gun at a stable speed and trajectory to ensure uniform coating.

End of work

Shut down the system: After the spraying is completed, first turn off the paint supply, then turn off the air source, and finally turn off the power of the electrostatic generator.

Cleaning and maintenance: Clean the spray gun in a timely manner to prevent the paint from drying up and blocking.

Previous:Is already the first one

Next:What is the difference between powder coating and liquid coating for auto parts?

Related Information

- HDA-90 Auto electrostatic spray gun

- What is the difference between powder coating and liquid coating for auto parts?

- Electrostatic Spray Gun: Make the Coating Stick to the Part

- Electrostatic Spray Gun: Why Does Charged Paint Stick Better, Waste Less, and Lo

- Why do liquid electrostatic spray guns to electric leakage and air leakage test

- How to choose a right liquid electrostatic spray gun?

- Why is one electrostatic spray gun better than 10 air spray guns?

- The liquid electrostatic spray gun industry will present the following developme

- What is the difference between Chinese brand electrostatic spray guns and Europe

- The HDA-100 liquid paint electrostatic spray gun

- The coating spraying process and automation equipment technology

- aluminum profile electrostatic spraying

- HDA-114 electrostatic controller of the manual electrostatic spray gun HDA-1020

- What's liquid spraying technology going on?

- How is the surface treatment industry in Turkey?

- HDA Electrostatic spray gun

- How is the industrial enterprises going on in 2023?

- Liquid Electrostatic spray solutions & automatic spray machines | hdaspraygun

- Why use liquid electrostatic spray gun in explosion-proof?

- china hot topics new energy in 2022

BACK

BACK HDA HOME

HDA HOME Navbar

Navbar