The coating spraying process and automation equipment technology

2025.03.04

The coating spraying process and automation equipment technology for glass bottle caps involve the following core points:

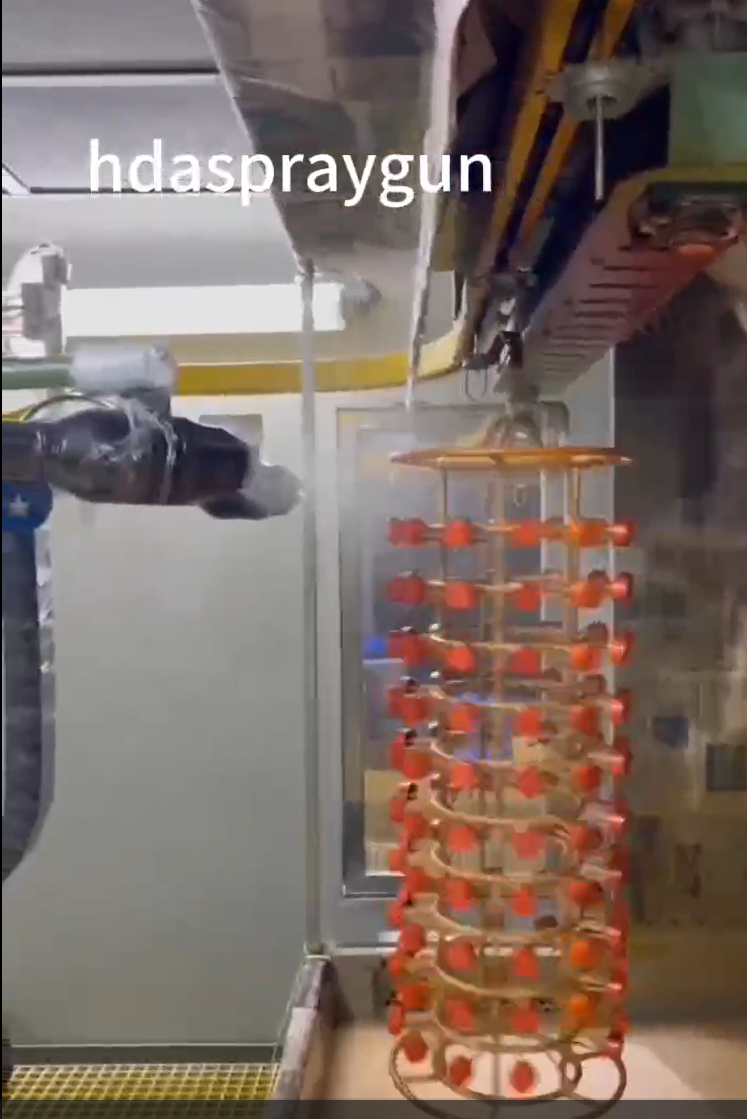

Electrostatic rotating bell spraying technology

This technology achieves efficient atomization and uniform coverage of coatings through the principle of electrostatic adsorption. The rotating clock design can improve spraying efficiency, especially suitable for multi-layer spraying processes of multi-color coatings or varnishes. Automated systems typically integrate dynamic rotation control modules to ensure the uniformity of bottle cap surface coating.

Special coating characteristic requirements

Glass adhesion: Glass paint should be used, and its composition formula should be adapted to the surface characteristics of the glass

Chemical resistance: The coating should have the ability to resist the erosion of diluents to avoid marking detachment caused by subsequent processes

Rapid curing: Some processes stack clear varnish on partially dried primer, requiring the coating to have rapid curing characteristics

Automated process optimization

Parameter control: Control the coating thickness (15-50μm) by adjusting parameters such as voltage (15-80kV) and atomization pressure (0.3-0.6MPa)

Quality inspection: The integrated optical inspection system monitors the integrity of the coating, and the automatic rejection rate of defective products can reach 99.8%

Energy efficiency ratio: Compared to traditional air spraying, the utilization rate of coatings is increased by 40-60%, and VOC emissions are reduced by 30%

Equipment compatibility design

The high-end system supports a bottle cap diameter range of 20-100mm and a speed adjustment accuracy of±5rpm, suitable for continuous production of different specifications of bottle caps. Some models are equipped with self-cleaning nozzles, which can achieve color cleaning within 5 minutes when switching coatings

Analysis and Application Guide of Electrostaticrotating bell Spray Gun Technology

1、Core technical principles

Electrostatic atomization and adsorption mechanism

The electrostaticrotating bell spray gun generates centrifugal force through the high-speed rotation of the rotary cup (with a no-load speed of 25000r/min and a load speed of 30000-60000r/min), breaking the coating into 50-100μm charged particles, which are directionally adsorbed onto the surface of the workpiece in a 15-80kV high-voltage electrostatic field.

This technology increases the utilization rate of coatings by 40% -60% and reduces VOC emissions by 30%.

Dynamic electric field configuration

Adopting the electric field design of workpiece grounding (anode) and negative high voltage of rotary cup (cathode), the intelligent adjustment system matches different workpiece shapes (such as curved surfaces and irregular parts) to achieve uniform coverage of 45.

2、Core structure and performance of equipment

Design of rotary bell component

Modular structure: integrates self-cleaning nozzle and dynamic sealing cover, completes coating switching and cleaning within 5 minutes, supports continuous production

High speed bearing system: using imported bearings, the speed adjustment accuracy is±5rpm, and the load speed can reach 50000r/min. 67

Material optimization: high-density aluminum alloy rotary cup head reduces weight (external size 100mm), reduces noise and maintenance costs by 67

Control system integration

Servo motor driven reciprocating spraying machine, achieving±0.1mm trajectory accuracy of 5

The optical detection system automatically eliminates defective products with a rejection rate of 99.8%

Support UV/hot air dual curing mode, complete surface drying in 3-5 minutes under 80-120℃conditions

|

Parameter item |

Control range |

|

Rotating speed |

30000-60000rpm |

|

Atomization pressure |

0.3-0.6MPa |

|

Electrostatic field voltage |

20-80kV |

|

Spray distance |

150-300mm |

Typical application scenarios

Metal products

Spraying of curved parts such as automotive components and electric vehicle frames, with a film thickness control accuracy of±5μm 67

Full coverage spraying of irregular parts such as doors, windows, and stair handrails, saving 30% -40% of paint

Wooden furniture

Multi layer spraying of primer/varnish for wooden doors and customized furniture, supporting synchronous curing process 5

UV coating cures quickly, increasing production efficiency by over 50%

Electronic appliances

Static shielding coating for household appliance shells, with adjustable film thickness of 15-50μm

Precision hardware anti-corrosion coating, resistant to alcohol solvent immersion for 24 hours without peeling off

Previous:The HDA-100 liquid paint electrostatic spray gun

Next:aluminum profile electrostatic spraying

Related Information

- HDA-90 Auto electrostatic spray gun

- What is the difference between powder coating and liquid coating for auto parts?

- Electrostatic Spray Gun: Make the Coating Stick to the Part

- Electrostatic Spray Gun: Why Does Charged Paint Stick Better, Waste Less, and Lo

- Why do liquid electrostatic spray guns to electric leakage and air leakage test

- How to choose a right liquid electrostatic spray gun?

- Why is one electrostatic spray gun better than 10 air spray guns?

- The liquid electrostatic spray gun industry will present the following developme

- What is the difference between Chinese brand electrostatic spray guns and Europe

- The HDA-100 liquid paint electrostatic spray gun

- The coating spraying process and automation equipment technology

- aluminum profile electrostatic spraying

- HDA-114 electrostatic controller of the manual electrostatic spray gun HDA-1020

- What's liquid spraying technology going on?

- How is the surface treatment industry in Turkey?

- HDA Electrostatic spray gun

- How is the industrial enterprises going on in 2023?

- Liquid Electrostatic spray solutions & automatic spray machines | hdaspraygun

- Why use liquid electrostatic spray gun in explosion-proof?

- china hot topics new energy in 2022

BACK

BACK HDA HOME

HDA HOME Navbar

Navbar