Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: Block A No336, Changqing North Road Chanan Town . dongguan China

Hotline:+86-13622624429

Air Electrostatic Manual Spray Gun 1020W/1020M

This manual contains important warnings and precautions. Please read it carefully before using the machine.

Keep this manual properly until the machine is scrapped. If lost or damaged, please apply to our company for a replacement.

Thank you for purchasing the Air Electrostatic Manual Spray Gun 1020 Series.

To ensure you can use this machine efficiently for a long time, please read the manual carefully before use. Fully understand each item, warnings, prohibitions and precautions specified in the specifications, and use it in the correct way.

This machine is used with a controller. Please be sure to read the controller's operation manual.

The machine described in this manual is equipment for spraying operations. It is only intended for use by personnel who have received training on usage methods and scope and fully understand the operation procedures.

If you have any questions about the content of the manual, please contact us at the address on the back cover. When contacting, please specify the "model" and "serial number".

1. For Your Safe Use of the Machine - 1

2. Overview -

3. Specifications -

4. Features - 7

5. Exploded Views and Parts Lists - 8

6. Installation - 13

7. Safety Management - 18

8. Pre-Operation Checks - 20

9. Operation Methods - 21

10. Maintenance - 24

11. Countermeasures for Poor Coating - 25

12. Troubleshooting and Handling - 27

13. Parts Replacement Sequence and Adjustment - 32

14. Maintenance Records - 38

15. Warranty Scope - 39

1. For Your Safe Use of the Machine - 1

2. Overview -

3. Specifications -

4. Features - 7

5. Exploded Views and Parts Lists - 8

6. Installation - 13

7. Safety Management - 18

8. Pre-Operation Checks - 20

9. Operation Methods - 21

10. Maintenance - 24

11. Countermeasures for Poor Coating - 25

12. Troubleshooting and Handling - 27

13. Parts Replacement Sequence and Adjustment - 32

14. Maintenance Records - 38

15. Warranty Scope - 39

Please fully understand the content of this manual and use it in accordance with the specified methods. Improper use contrary to the manual may result in personal injury and machine damage.

The safety precautions described below are the minimum safety measures to be followed when using our company's products. Other safety precautions are not unnecessary. You must also comply with other relevant laws, regulations, and the rules and procedures of the user's unit.

Precautions are classified into three types:

• Warning: Indicates situations that may cause personal injury. It draws attention and provides methods to avoid such situations.

• Caution: Indicates situations that may cause machine damage. It draws attention and provides methods to avoid such situations.

• Note: Indicates important methods and useful information.

In addition, the items recorded in the "Caution" section may also lead to serious consequences under certain circumstances. Therefore, the safety precautions and fault prevention content must be observed.

The product covered by this manual is the 1020W/1020S air electrostatic manual spray gun.

This machine is a manual spray gun installed on a spraying line equipped with exhaust equipment. It atomizes paint with air for spraying.

This machine must be used in a spray booth that meets the capabilities specified by relevant regulations and laws or under equivalent ventilation conditions.

If you have any questions about the intended use of this machine or the materials to be used, please consult our company.

Use under conditions other than those mentioned above (except with the approval of our company) is improper and may cause accidents. Please pay full attention.

1. The workpiece to be sprayed must be properly grounded. Do not use uncharged hooks. Regular cleaning is required to maintain conductivity.

2. All conductors and solvent barrels in the spray booth must be grounded. The entire floor must have an antistatic structure with a resistance of 1MΩ or less.

3. For open-type spray booths, the floor area includes the opening width + 1.5 meters on both sides and

2.5 meters in front of the opening. The entire floor of this area must have an antistatic structure with a resistance of 1MΩ or less and be kept clean.

4. Operators must work with bare hands or wear conductive gloves.

5. Wear electrostatic shoes (in accordance with JIS T8103 standards).

6. Maintain good ventilation during operation.

7. When cleaning the spray gun, always reduce the paint pressure and air pressure to zero and turn off the power of the control panel before proceeding.

8. Do not use metal brushes to clean the nozzle.

9. Do not immerse the spray gun, hoses, etc., in solvents.

10. Do not drag hoses on the ground; instead, hang them up.

11. The exhaust devices (pipes, fans) in the spray booth must be kept clean and regularly cleaned.

12. The distance between the nozzle tip and the workpiece must be at least 150mm.

13. Keep a fire extinguisher on hand for emergencies.

14. This machine is only for use by personnel who have received safety operation training.

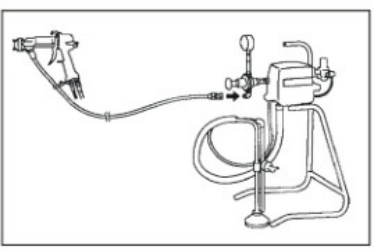

The Air Electrostatic Manual Spray Gun 1020W/1020S must be used with Controller 114, a paint supply device (such as a feed pump, pressure tank, etc.), and an electrostatic nozzle.

|

|

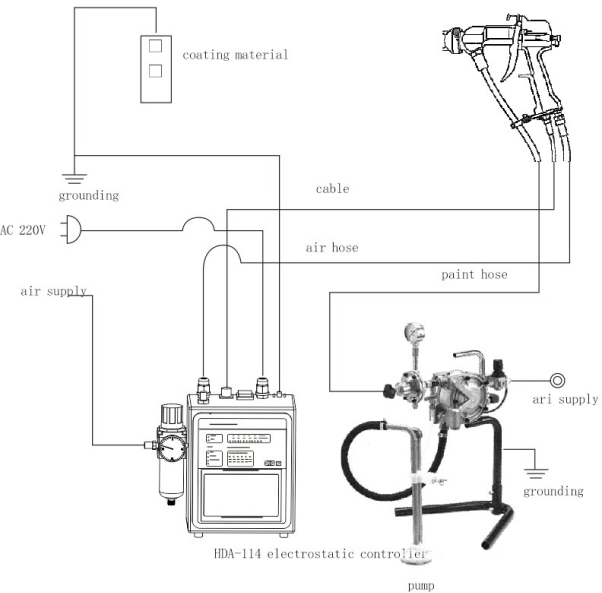

Example of Air Electrostatic Spraying System Composition (Taking 1020W as an Example)

For the connection method of each spray gun, please refer to "6. Installation".

• Grounding: Connection Cable

• AC 220V: Air Hose

• Air Source: Paint Hose

• Grounding: Controller 114

• Paint Supply Device

The controller must be installed outside the spray booth, at a distance of more than 1.5 meters from the opening. -3

1. Component Names of 1020W

• H

•Hook

•Gun Barrel

•Spray Width Air Adjustment Valve

•Paint Regulator

•Gun Grip

•Trigger

•Paint Hose (Milky White)

•Air Hose (Orange-Red)

•Connection Cable

|

Item |

Specification |

|

(1) Model |

1020 |

|

(2) Maximum Voltage |

DC-60 KV |

|

(3) Overall Length (Gun Body) |

206mm; 231mm with flat nozzle installed; 238mm with round nozzle installed |

|

(4) Gun Weight (Excluding Cable, Hoses, Nozzle) |

530g |

|

(5) Power Cable Length |

10m (extendable up to 30m) |

|

(6) Paint Pressure |

Normal: 0~0.3Mpa; Maximum: 0.62Mpa |

|

(7) Air Pressure |

Normal: 0.05~0.4Mpa; Maximum: 0.62Mpa |

1. Control Generator (the HDA-114 electrostatic controller for HDA-1020 spray gun)

|

Item |

Specification |

|

(1) Model |

114 |

|

(2) Input Voltage |

110/220V/240V |

|

(3) Frequency |

50/60Hz |

|

(4) Power Capacity |

80VA DC-60KV |

|

(5) Transmission Voltage |

AC24V±2V |

|

(6) Transmission Frequency |

20kHz±1kHz |

|

(7) Rated Current |

80A (Current when the electrode at the nozzle tip is short-circuited) |

|

(8) Overcurrent Protection |

Overcurrent Interruption Type (80A setting) |

|

(9) Dimensions (Width x Height x Thickness) |

200mm x 250mm x 150mm |

|

(10) Operating Environment |

Temperature: 0~45°C; Humidity: 20~85% (No condensation) |

|

(11) Weight |

6.0 kg |

1. Power Cables

|

Item |

Specification |

|

(1) Connection Cable Size |

6m, 8m, 10m |

|

(2) Extension Cable Size |

20m (20~30m optional) |

1. Air Hose

|

Item |

Specification |

|

Type |

Part No. 747-01-005 |

|

Material |

Polyurethane (with built-in ground wire) |

|

(3) Inner Diameter x Outer Diameter |

Φ8.5 x Φ12 |

1. Paint Hose

|

Item |

Specification |

|

(1) Part No. |

747-01-004 |

|

(2) Material |

Double-layer Hose (Inner Layer: PTFE; Outer Layer: Polyethylene) |

|

(3) Hose Diameter (Inner x Outer) |

Φ5 x Φ10 |

|

(4) Hose Length |

5m, 10m (20~30m optional) |

|

Note |

Some paints such as phenolic resin may cause discoloration or deformation of the hose. |

The spray width adjustment valve is located on the left side for easy adjustment. The spray gun is lightweight with low operating force, ensuring no fatigue even during long-term use.

In addition to traditional electrostatic nozzles, the use of small and lightweight round nozzles and flat

nozzles provides superior coverage, increasing paint transfer efficiency and significantly saving paint.

Maintenance parts are modularized for simple replacement. Complex adjustments during assembly and seal tightening during use are not required.

The plunger of the paint valve seat is made of cemented carbide, and the gasket adopts a spring-actuated seal and U-shaped gasket, ensuring durability and long service life.

For workpieces with complex shapes and multiple cavities, the rotary air jet round nozzle (with the highest paint transfer efficiency among air atomization methods) is recommended. For flat workpieces with few cavities, the wide-angle multi-stage jet flat nozzle is suitable. Even for metallic topcoat spraying, excellent film results can be achieved.

Suitable for most conductive paints, including general paints, metallic paints, and water-based paints.

The controller (114) is equipped with overcurrent protection, high-speed voltage cutoff via electronic switch, and buzzer alarm, fully ensuring operator safety. The high-voltage electrostatic generator is built into the gun, minimizing the high-voltage electrostatic range and greatly improving safety

Exploded Views and Parts Lists

|

No. |

Part No. |

Name |

Qty |

Remarks |

No. |

Part No. |

Name |

Qty |

Remarks |

|

1 |

101-01-012 |

- |

1 |

- |

32 |

102-01-005 |

Type Clip |

- |

- |

|

2 |

102-01-021 |

Handle Base |

1 |

- |

33 |

102-01-021 |

Plunger Seat |

1 |

- |

|

3 |

102-01-022 |

Cable Connector |

- |

- |

34 |

101-01-009 |

Plunger Seat Gasket |

1 |

- |

|

4 |

102-01-001 |

Air Pipe Connector |

1 |

- |

35 |

101-01-015 |

High-Voltage Pack Insulation Gasket |

1 |

- |

|

5 |

101-02-002 |

Gun Barrel |

1 |

- |

36 |

201-09-003 |

E-Type Retaining Ring |

1 |

- |

|

6 |

101-01-011 |

Three-Way Connector |

1 |

- |

37 |

201-01-008 |

Seal Ring |

1 |

- |

|

7 |

104-01-001 |

High- Voltage Pack |

1 |

- |

38 |

- |

Seal Ring |

1 |

- |

|

8 |

101-01-013 |

Bushing |

1 |

- |

39 |

- |

- |

- |

- |

|

9 |

101-01-001 |

V-Ring Seal |

1 |

- |

40 |

201-01-020 |

Seal Ring |

1 |

- |

|

10 |

201-04-001 |

Seal Gasket |

1 |

- |

41 |

201-01-001 |

Seal Ring |

2 |

- |

|

11 |

101-02-001 |

Plunger |

1 |

- |

42 |

201-01-002 |

Seal Ring |

1 |

- |

|

12 |

102-01-010 |

- |

- |

- |

43 |

201-01-005 |

Seal Ring |

- |

- |

|

13 |

102-01-011 |

Push Rod Gasket |

1 |

- |

44 |

201-01-004 |

Seal Ring |

- |

- |

|

14 |

102-01-013 |

Air Push Rod |

1 |

- |

45 |

201-01-003 |

Seal Ring |

1 |

- |

|

15 |

102-01-009 |

Gasket |

1 |

- |

46 |

- |

M3 Hex Screw |

1 |

- |

|

16 |

102-01-012 |

Air Valve Guard Ring |

1 |

- |

47 |

201-02-002 |

M4 Hex Screw |

7 |

- |

|

17 |

101-01-004 |

Air Valve Seal Gasket |

1 |

- |

48 |

- |

- |

- |

- |

|

18 |

101-01-008 |

- |

1 |

- |

49 |

201-02-003 |

M2.0 Cross Screw |

4 |

- |

|

19 |

- |

Spring |

1 |

- |

50 |

201-03-001 |

M2.5 Hex Nut |

1 |

- |

|

20 |

102-01-007 |

Spring |

1 |

- |

52 |

101-01-014 |

High-Voltage Pack Interconnection Insulation Sheet |

- |

- |

|

- |

102-01-008 |

Spring |

1 |

- |

53 |

102-01-004 |

Trigger |

1 |

- |

|

- |

102-01-016 |

Paint Adjustment Knob Seat |

1 |

- |

54 |

102-01-002 |

M4 Custom Nut |

1 |

- |

|

23 |

102-01-016 |

Positioning Rod |

- |

- |

55 |

101-01-007 |

Oil Pipe Support Frame |

1 |

- |

|

24 |

102-01-015 |

Knob |

- |

- |

56 |

201-02-004 |

Cross Nylon Screw |

- |

- |

|

- |

102-01-019 |

Positioning Rod |

- |

- |

57 |

747-01-004 |

Paint Pipe |

6m |

Customizable |

|

|

26 |

- |

Air Adjustment Knob Seat |

- |

- |

58 |

747-02-002 |

Cable |

6m |

- |

|

|

27 |

101-01-010 |

Air Duct |

1 |

- |

59 |

747-01-005 |

Air Pipe |

6m |

Customizable |

|

|

28 |

101-01-017 |

Seal Gasket |

1 |

- |

- |

- |

Conical Spring |

1 |

- |

|

|

29 |

102-01-014 |

Hook |

1 |

- |

A |

- |

Bushing Assembly |

- |

- |

|

|

30 |

- |

- |

- |

- |

B |

- |

Needle Assembly |

1 Set |

- |

|

|

31 |

102-01-003 |

Trigger Latch |

1 |

- |

C |

747-02-001 |

Handle Base Assembly |

1 Set |

- |

|

1. Air Electrostatic Manual Spray Gun (1020M) Exploded View

(Review the exploded view diagram on page -10 for part positions)

|

No. |

Part No. |

Name |

Qty |

Remarks |

No. |

Part No. |

Name |

Qty |

Remarks |

|

1 |

101-01-012 |

Handle |

1 |

- |

32 |

102-01-005 |

Type Clip |

- |

- |

|

2 |

102-01-021 |

Handle Base |

1 |

- |

33 |

- |

- |

1 |

- |

|

- |

- |

Cable Connector |

- |

- |

34 |

- |

- |

1 |

- |

|

4 |

102-01-001 |

Air Pipe Connector |

1 |

- |

35 |

101-01-015 |

High-Voltage Pack Insulation Gasket |

1 |

- |

|

5 |

101-02-002 |

Gun Barrel |

- |

- |

- |

201-09-003 |

E-Type Retaining Ring |

1 |

- |

|

- |

101-01-011 |

Three-Way Connector |

1 |

- |

- |

201-01-008 |

Seal Ring |

1 |

- |

|

- |

- |

High-Voltage Pack |

1 |

- |

- |

- |

Seal Ring |

1 |

- |

|

- |

- |

Bushing |

1 |

- |

- |

- |

- |

- |

- |

|

9 |

101-01-001 |

V-Ring Seal |

1 |

- |

- |

201-01-020 |

- |

1 |

- |

|

10 |

201-04-001 |

- |

1 |

- |

41 |

201-01-001 |

Seal Ring |

2 |

- |

|

- |

101-02-001 |

Plunger |

1 |

- |

42 |

- |

Seal Ring |

1 |

- |

|

- |

- |

Paint Push Rod |

1 |

- |

43 |

201-01-005 |

- |

- |

- |

|

13 |

- |

Push Rod Gasket |

- |

- |

- |

201-01-004 |

Seal Ring |

- |

- |

|

- |

102-01-013 |

- |

1 |

- |

45 |

201-01-003 |

Seal Ring |

- |

- |

|

15 |

102-01-009 |

Gasket |

1 |

- |

46 |

- |

- |

1 |

- |

|

16 |

102-01-012 |

- |

1 |

- |

47 |

201-02-002 |

- |

- |

- |

|

- |

101-01-004 |

Air Valve Seal Gasket |

1 |

- |

- |

- |

- |

- |

- |

|

18 |

- |

- |

1 |

- |

49 |

- |

M2.0 Cross Screw |

4 |

- |

|

- |

102-01-006 |

Spring |

- |

- |

50 |

- |

- |

1 |

- |

|

20 |

102-01-007 |

Spring |

1 |

- |

52 |

101-01-014 |

High-Voltage Pack Interconnection Insulation Sheet |

- |

- |

|

21 |

102-01-008 |

Spring |

1 |

- |

53 |

102-01-004 |

Trigger |

1 |

- |

|

22 |

- |

Paint Adjustment Knob Seat |

1 |

- |

54 |

102-01-020 |

Oil Pipe Adapter |

- |

- |

|

- |

- |

Positioning Rod |

- |

- |

- |

101-01-023 |

- |

1 |

- |

|

- |

102-01-015 |

- |

- |

- |

56 |

101-01-024 |

Oil Pipe Connector |

- |

- |

|

25 |

- |

- |

- |

- |

- |

201-05-015 |

Paint Pipe |

- |

- |

|

26 |

102-01-020 |

- |

- |

- |

58 |

101-01-022 |

Oil Pipe Sheath |

1 |

- |

|

- |

101-01-010 |

Air Duct |

- |

- |

- |

- |

O-Ring |

- |

- |

|

28 |

101-01-017 |

Seal Gasket |

1 |

- |

- |

- |

- |

- |

- |

|

29 |

- |

Hook |

- |

- |

A |

- |

- |

- |

- |

|

30 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

31 |

102-01-003 |

Trigger Latch |

1 |

- |

- |

- |

- |

- |

- |

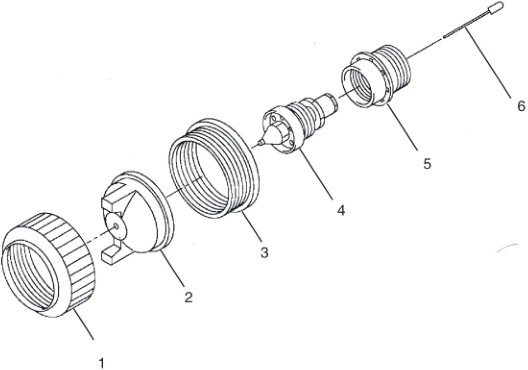

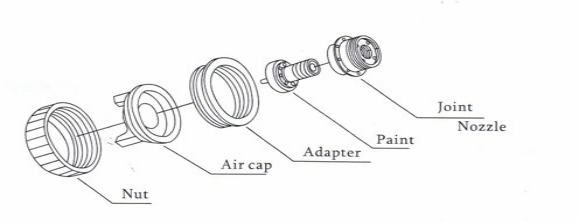

1. Fan Nozzle Exploded View

(Review the exploded view diagram on page -12 for part positions)

No

Part No.

Name

Quantity

Remarks

No

Part No.

Name

Quantity

Remarks

1

-

70 Air Cap

-

-

4

HD- 0601110

1

-

-

-

2

-

Paint Nozzle

1

-

5

-

Nozzle Connector

1

-

3

-

Nut

-

-

6

HD- 0601110

2

Electrode

1

-

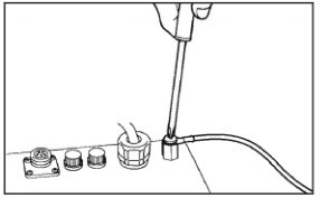

Installation

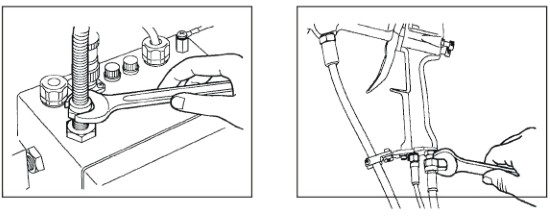

Connect the air source to the air regulator on the high-voltage electrostatic generator. (Thread size: PF1/4)

Firmly connect the ground wire to the controller using a Phillips screwdriver.

Use a wire of 3.5mm² or larger for the ground wire of the controller unit. Wire it in a location with Type 1 grounding (ground resistance less than 10Ω) and ensure it is securely fastened to prevent loosening.

grounding

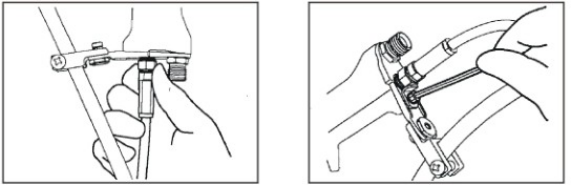

When installing the power cable on the spray gun, fasten it by hand.

After tightening the power cable, secure the plug. If the installation position is incorrect, do not force it; retract the nut and re-tighten.

Do not use tools to forcefully tighten the cable, as this may damage the connector. Do not over-tighten; always secure it with the plug.

When bundling the power cable, air hose, and paint hose with cable ties, do not pull them too tightly; leave some slack. Over-tightening the power cable during use may cause wire breakage

Connect one end of the air hose to the connector at the rear of the gun grip (next to the electrostatic cable), and the other end to the "Air Output" port on the controller, then tighten it. (Thread size: PF1/4; use a 17mm

Connect one end of the paint hose connector to the front connector at the end of the gun handle (in front of the connection cable), and the metal connector at the other end to the paint supply device. (Thread size: PF1/4)

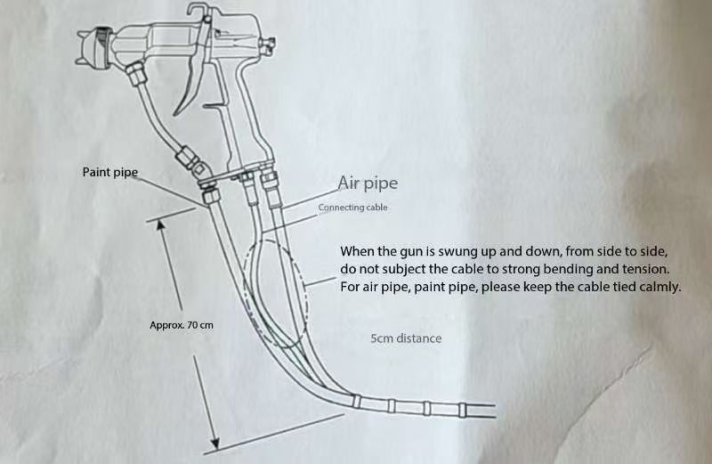

(1) To prevent a decrease in the strength and service life of the connection cable, follow these bundling precautions:

① The bundled part of the connection cable must be approximately 70cm away from the end of the gun handle.

② Bundle the air pipe, paint pipe, and cable loosely to avoid excessive bending or tension when moving the gun up, down, left, or right.

③ For bundling beyond 70cm from the end of the gun handle, use resin straps or plastic ties with 5cm intervals. Bundle loosely. Do not wrap with plastic ties or wide spiral hoses layer by layer, as this will make the bundled part rigid, leading to breakage or damage of the connection cable and pipes.

(When moving the gun up, down, left, or right, do not subject the cable to excessive bending or tension. Bundle the air pipe, paint pipe, and cable loosely.)

(Approx. 70cm distance; 5cm interval between straps)

(2) Operate and bundle the connection cables correctly to avoid excessive bending or pulling of the connection cable, air pipe, and paint pipe during spraying, which may reduce their strength or cause breakage.

(3) Do not step on the connection cable, especially on metal gratings, as this may cause breakage.

(4) Do not wrap the connection cable itself with plastic ties layer by layer to reinforce or prevent contamination; this will reduce cable strength and may cause breakage.

(5) Do not immerse the connection cable in solvents or paint for a long time, as this will significantly reduce its service life and strength.

(6) After cleaning the cable, wipe off any surface solvents or dry it with compressed air.

Do not use metal ties for bundling. Residual static electricity on metal parts may cause a tingling sensation to the operator

① Assemble the nut, air cap, and air cap holder.

② Assemble the paint nozzle and nozzle connector.

③ Insert the electrode needle into the paint nozzle, then install the assembled part ② onto the gun extension and tighten with a Hex8 wrench.

④ Install the assembled part ① onto the gun extension and tighten by hand.

Components: Electrode, Gun Extension, Paint Nozzle, Nozzle Connector, Nut, Air Cap, Air Cap Holder

Since the parts are made of resin, over-tightening may damage the internal threads of the nozzle connector. Be extra careful during installation and removal.

For operational safety and long-term use of the spray gun, pay attention to the following items before, during, and after operation:

(1) The controller must be grounded.

The ground wire of the controller is fundamental for safe operation. The spray gun's ground is also derived from the controller, so ensure the ground wire is properly grounded.

(2) The workpiece to be coated must be kept grounded at all times.

Workpieces are generally grounded via the conveyor, but paint adhesion on the contact parts of the hanger may cause poor conductivity, leading to static charge accumulation on the workpiece, which can generate sparks and cause fires. Therefore, regularly remove paint from the hanger.

(3) All metal objects in the spray booth must be grounded.

High voltage in the spray booth ionizes the air around the spray gun. Ungrounded metal objects may become charged and generate sparks. Therefore, metal objects such as the spray gun mounting platform and safety barriers in the spray booth must be securely grounded. Do not place unused paint cans, tools, or other metal objects in the spray booth.

Solvent containers must be grounded even if placed near the entrance/exit outside the spray booth.

(4) Operate the spray gun with bare hands.

The grip of the spray gun is grounded via the control box. Wearing gloves during operation may cause static charge accumulation on the human body; contact with other grounded objects may result in electric shock or fire. If gloves must be worn, cut a hole in the palm area to ensure direct skin contact with the gun grip.

(5) Wear electrostatic shoes during operation.

Operators engaged in electrostatic spraying or working near the spray booth must wear electrostatic shoes to prevent static charge accumulation. Regularly check to ensure no paint clumps adhere to the shoes.

(6) The floor of the spray area must have an antistatic structure. For closed spray booths, the entire floor must meet this requirement. For open spray booths, the area including 1.5 meters on both sides of the opening and 2.5 meters in front of the opening must have an antistatic structure with a resistance of 1MΩ or less and be kept clean.

(7) When cleaning the nozzle, always turn off the power of the control box and ground the nozzle tip first. High voltage may be present during nozzle cleaning, which can cause fires. Turn off the power switch when interrupting or ending operations.

(8) Do not use metal brushes to clean the nozzle.

The nozzle is critical to the spray gun's performance. Using a metal brush may damage the nozzle, resulting in uneven atomization. Use the brush provided with the machine.

The nozzle is a precision part; keep it clean at all times and avoid over-tightening or damage. -18

(9) Do not immerse the spray gun body, power cable, or hoses in solvents.

The electrostatic spray gun is an electrical device; improper immersion in solvents may cause malfunctions.

(10) Do not drag the power cable or hoses on the ground; hang them from the ceiling or walls as much as possible. (When using conductive paint, hang the paint hose with insulating materials such as rubber hoses.)

Dragging cables and hoses on the ground may easily cause damage.

(11) Keep the interior of the spray booth and exhaust devices (ventilation pipes, fans) clean and perform

regular cleaning.

In the event of a fire, volatile paint gases in the spray booth and exhaust devices will act as fuel, exacerbating the disaster.

(12) Fully drain condensed water from air transformers, air compressors, etc.

Moisture in the air may cause poor spraying, alarm activation, or safety circuit operation. Pay close attention to moisture removal.

(13) Maintain a distance of at least 150mm between the nozzle tip and the workpiece.

By design, the potential of the electrostatic spray gun nozzle automatically decreases when close to the ground. However, when the paint pump is used with insulation (for low-resistance paints such as metallic paints, woodworking paints, water-based paints), the pump's potential will not decrease, increasing the risk of sparks.

Consider unexpected situations such as workpiece swinging or falling, and maintain a sufficient spraying distance.

(14) If using an insulation table, keep it at least 500mm away from surrounding objects. Before touching it, turn off the control box power and ground it.

Low-resistance paints conduct electricity similarly to wires; contact with the paint container may result in electric shock. Install a grounded safety barrier near passageways to prevent accidental contact by unauthorized personnel.

Keep a fire extinguisher on hand for emergencies.

(15) Do not pull the trigger toward people. Residual pressure may cause paint to spray even after operation or when paint/air pressure is not applied.

(16) Before operation, check for air and paint leaks. Regularly inspect for loose screws during use to avoid accidents.

(17) Comply with current regulations when using and installing this machine.

[Occupational Safety and Health Regulations, Safety and Health Measures for Electrostatic Spraying]

Do not allow personnel unfamiliar with safe operation to use this machine.

(1) Open the air valve, set the air regulator to 3~4kgf/cm², and supply air to the spray gun. Check for air leaks at the hose connections.

(2) Hold the gun grip, turn on the controller power switch (green light illuminates). No high-voltage static electricity is generated at the nozzle tip at this time.

(3) Pull the trigger to spray air from the nozzle. The pneumatic switch inside the controller will activate, generating high-voltage static electricity (red light illuminates). When the red light is on, high-voltage static electricity is present at the nozzle tip (no high-voltage static electricity when the switch on the gun grip is OFF).

Turn off the control box power switch after inspection.

This device can achieve electrostatic effects with most synthetic resin paints (except some special types), so no special mixing is required. However, to enhance electrostatic effects, adjust the solvent as needed.

Some low-resistance paints may not achieve the expected electrostatic effect. Verify the paint resistance with a paint resistance meter. Good results are generally achieved when the paint resistance is adjusted to 15~70MΩ·CM.

To check the electrostatic effect: Ground a 20~30mm steel pipe and spray directly at it. A good electrostatic effect is indicated if the paint film forms on the back of the pipe.

Most conductive paints with extremely low resistance (such as metallic paints) cannot achieve significant electrostatic effects. During high-voltage output, the high-voltage cutoff circuit of the control box will activate, triggering the alarm buzzer and cutting off the high voltage. Turning off the control box power switch will reset the alarm.

When using paints and solvents with a flash point 5°C or higher than room temperature, always activate the ventilation device.

For questions about paint compatibility with the spray gun and equipment, contact our company for consultation. -20

(1) Load Paint into the Paint Supply Device

The standard viscosity for this machine is 9~30 seconds/FC#4, but it can vary depending on paint type, solvent type, workpiece shape, film thickness, and other conditions. Before loading the paint, always measure its resistance.

(2) Start the Paint Supply Device and Deliver Paint to the Spray Gun

Set the air regulator to low pressure (approximately 0.1Mpa), start the pump, and draw in the paint. Use the paint regulator at the pump inlet/outlet to adjust the pump pressure to approximately 0.2~0.3Mpa.

Double-check the control box to ensure the power switch is in the OFF position.

(3) Spray Paint from the Gun

Set the atomizing air pressure to 0Mpa (no air spray), pull the trigger, and spray paint from the gun. If there is residual air in the paint hose, the paint will spray intermittently. Continue spraying until no air remains.

Adjust the paint spray rate using the paint regulator at the rear of the gun: turn left to increase the spray rate, turn right fully to stop spraying. During breaks, tighten the paint regulator to stop spraying or reduce

the paint supply pressure.

(4) Adjust the Atomizing Air Pressure and Verify Atomization

Set the atomizing air pressure to 0.2~0.3Mpa. Pull the trigger to atomize the paint, select a suitable nozzle, and adjust the atomizing air pressure as needed.

This machine uses an internal pressure sealing system. To prevent malfunction of the paint plunger, a small amount of air may escape from the plunger area. A slight air release sound is normal.

The atomizing air adjustment valve on the top of the gun body is usually used in the fully open (left-rotated) position. Adjust it according to the spray width shape or atomization fineness. Adjust the spray width using the spray width adjustment valve on the left side of the gun: turn left to increase the width, turn right to decrease it.

Do not use the atomizing air adjustment valve on the gun. Only use the spray width adjustment valve on the left side, which is usually used in the fully open (left-rotated) position. Adjust it according to the spray width shape or atomization fineness.

Check for air leaks at the air hose connections and when the trigger resets. The control box power is activated during spraying; high-voltage static electricity is generated even when not spraying. -21

(1) Turn the control box power switch to the ON position. Pull the trigger; the red light illuminates, indicating high-voltage output at the nozzle tip. No high-voltage electricity is generated when the switch on the gun grip is OFF.

Before turning on the control box power switch, confirm that the control box is properly grounded.

Never wear gloves or rubber-soled shoes when holding the spray gun. The gun grip maintains zero potential when grounded via the control box, so no electric shock will occur when held with bare hands.

(2) Start the spraying operation. The 1020W/1020S allows voltage adjustment between 20~60Kv.

(3) When interrupting or ending the spraying operation, always turn off the control box power switch.

Do not place the spray gun on the workbench or leave it unattended when the control box power switch is ON.

For low-resistance paints (2MΩ·CM or less), place the paint pump on an insulation table before use. The paint pump will be charged with high voltage during operation; never touch it while high-voltage output is active. Before touching or refilling paint, turn off the power and ground the pump with a grounding rod.

(1) Turn off the electrostatic controller power. Hold the gun with one hand during operation; do not place it

on the ground.

(2) Set the atomizing air regulator to 0Mpa.

(3) Set the drive pressure of the paint supply device to 0Mpa.

(4) Spray residual paint from the nozzle to release residual pressure.

(5) To discharge residual static electricity, slowly ground the nozzle tip without pulling the trigger.

(6) Use a cloth dipped in solvent to clean paint residues from the nozzle and spray gun. Remove and clean the air duct (for round nozzles) or air cap (for flat nozzles).

To prevent accidental paint spraying due to unintended trigger pulls when not in use, close the paint regulator of the spray gun.

When cleaning the nozzle and air cap, keep the gun pointed downward to prevent solvent from entering the extension tube.

Do not immerse the spray gun body, power cable, or paint hose in solvent after cleaning or operation. The electrostatic spray gun is an electrical device; although seals prevent solvent ingress, long-term immersion will reduce durability and cause malfunctions.

For two-component chemically curing paints or easily precipitating paints, clean the equipment after each use in accordance with "4. Handling for Extended Inactivity".

(1) Turn off the control box power.

(2) Set the atomizing air regulator to 0MPa.

(3) Remove the suction pipe from the paint tank.

(4) Drive the paint supply device at low pressure (0.1Mpa) to drain residual paint from the pump.

(5) Pull the gun trigger to spray residual paint from the nozzle.

(6) Draw solvent into the paint pipe and discharge it through the return pipe. Repeat until the pump is clean.

(7) Discharge solvent from the nozzle to clean the interior of the hose and gun.

(8) Stop the pump and release residual pressure from the nozzle.

(9) Use a cloth dipped in solvent to clean paint residues from the nozzle and spray gun. Remove the nozzle and clean paint from the valve seat between the gun and nozzle.

Wait 10 seconds after turning off the control box power before cleaning. Over 90% of fires caused by electrostatic spray guns occur during nozzle cleaning. Always turn off the power first. Keep a fire extinguisher on hand for emergencies.

In case of abnormalities during operation, immediately turn off the control box power and reduce air and

paint pressure to zero.

Dispose of waste cleaning solvent in accordance with regulations: recycle it using a solvent recovery device or entrust it to a licensed industrial waste disposal company. -23

(1) Keep the spray gun clean at all times. Do not immerse the gun body in solvent during cleaning; hold the gun and gently clean it with a soft brush or cloth dipped in solvent.

(2) Do not disassemble the gun except for troubleshooting. Disassembly is only permitted when replacing parts due to malfunctions to ensure the gun body's insulation.

(3) Always hang the spray gun on the hook when not in use. Turn off the control box power even for short periods of inactivity.

(4) The 1020W/1020S spray gun is lightweight with a resin body designed for sufficient strength. Avoid dropping it during use.

(5) Slight heating at the rear upper part of the gun due to high-voltage generator operation is normal and not a malfunction.

(1) Thoroughly clean the nozzle after each operation.

(2) To clear a clogged nozzle, do not use metal wire or tools to poke it. Soak it in solvent first, then blow it clean with compressed air. Do not use metal brushes for cleaning.

(3) Regularly clean the nozzle during operation. Paint adhesion on the nozzle will cause poor atomization and reduce electrostatic effects.

(1) Keep them clean and free of paint or other debris.

(2) Avoid mechanical damage (e.g., stepping on, crushing, or rolling over them).

Turn off the control box power and release air/paint pressure before performing maintenance.

Ensure conductive containers are grounded during cleaning.

Multiple coating defects may occur simultaneously

Cause

Countermeasure

(1) Insufficient atomizing air pressure.

(1) Increase the atomizing air pressure.

(2) Excessive paint output.

(2) Reduce the paint output or increase the atomizing air pressure.

(3) Excessively high paint viscosity.

(3) Reduce the paint viscosity.

(4) Bent grounding electrode needle.

(4) Straighten or replace the electrode needle.

(5) Damaged nozzle.

(5) Replace the nozzle.

1. Excessive Paint Rebound

|

Cause |

Countermeasure |

|

(1) Excessively long spraying distance. |

(1) Maintain a spraying distance of 150~200mm. |

|

(2) Excessively high atomizing air pressure. |

(2) Reduce the atomizing air pressure. |

|

(3) Incomplete grounding of the workpiece. |

(3) Ensure proper grounding of the workpiece. |

|

(4) Slow exhaust speed. |

(4) Increase the exhaust speed. |

1. Low Paint Transfer Efficiency

|

Cause |

Countermeasure |

|

(1) Poor grounding of the workpiece. |

(1) Remove paint from the hanger and ensure complete grounding. |

|

(2) Excessively high atomizing air pressure. |

(2) Adjust the atomizing air pressure appropriately. |

|

(3) Excessively long spraying distance. |

(3) Maintain a spraying distance of 150~200mm. |

|

(4) Low supply voltage. |

(4) Increase the output voltage on the controller. |

|

(5) Fast exhaust speed. |

(5) Reduce the exhaust speed. |

1. Paint Adhesion on Nozzle or Filamentous Defects on Workpiece

|

Cause |

Countermeasure |

|

(1) Excessively high paint viscosity. |

(1) Reduce the paint viscosity. |

1. Sand-like Coating Surface

|

Cause |

Countermeasure |

|

(1) Poor spray atomization. |

(1) Refer to Section 1 "Poor Atomization of Spray" in this chapter. |

|

(2) Dust in the spray booth or on the workpiece surface. |

(2) Install a dust filter at the air intake of the spray booth and clean the workpiece surface. |

|

(3) Contaminated atomizing air. |

(3) Clean or replace the air path filter. |

|

(4) Poor pigment dispersion in the paint. |

(4) Fully filter the paint. |

1. re on Coating

|

Cause |

Countermeasure |

|

(1) High temperature in the spray booth. |

(1) Adjust the room temperature. |

|

(2) Excessively high workpiece temperature. |

(2) Adjust the drying oven to lower the workpiece temperature. |

|

(3) Fast air intake/exhaust speed. |

(3) Adjust the air speed to 0.5~1.0m/sec at the workpiece surface. |

1. Rebound Phenomenon

|

Cause |

Countermeasure |

|

(1) Contaminated workpiece. |

(1) Thoroughly clean and degrease the workpiece. |

|

(2) Contaminated atomizing air. |

(2) Clean or replace the air path filter. |

|

(3) Poor exhaust in the drying oven. |

(3) Ensure adequate exhaust. |

Paint Sagging on Coating Surface

|

Cause |

Countermeasure |

|

(1) Excessively thick coating. |

(1) Reduce the paint output or increase the spray gun movement speed. |

|

(2) Excessively low paint viscosity. |

(2) Increase the paint viscosity. |

|

(3) High humidity in the spray booth. |

(3) Adjust the humidity using air conditioning or other equipment. |

1. Thin Coating

|

Cause |

Countermeasure |

|

(1) Insufficient paint output. |

(1) Adjust the paint output and spray gun movement speed; consider multiple coats. |

|

(2) Excessively low paint viscosity. |

(2) Increase the paint viscosity. |

1. Pinholes in Coating

|

Cause |

Countermeasure |

|

(1) Contaminated atomizing air. |

(1) Clean or replace the air path filter. |

|

(2) Excessively high workpiece temperature. |

(2) Lower the workpiece temperature. |

|

(3) Insufficient drying of the primer. |

(3) Ensure thorough drying of the primer. |

|

(4) Short setting time. |

(4) Adjust the setting time. |

1. White Streaks on Coating

|

Cause |

Countermeasure |

|

(1) High temperature and humidity in the spray booth. |

(1) Inspect the air conditioning equipment. |

1. Blistering on Coating

|

Cause |

Countermeasure |

|

(1) Contaminated atomizing air. |

(1) Clean or replace the air path filter. |

|

(2) Insufficient drying after water washing. |

(2) Ensure thorough drying. |

|

(3) Excessively thick coating. |

(3) Reduce the paint output. |

|

(4) Excessively high drying oven temperature. |

(4) Adjust the temperature to an appropriate level. |

Poor Spray Width Shape

|

Cause |

Countermeasure |

|

(1) Paint or dust adhesion on the nozzle's atomizing air and paint outlets. |

(1) Thoroughly clean with a brush dipped in solvent and filter the paint. |

|

(2) High paint viscosity. |

(2) Reduce the viscosity. |

|

(3) Damaged nozzle tip. |

(3) Repair or replace the nozzle. |

|

(4) Poor spray width adjustment. |

(4) Adjust using the spray width adjustment knob. |

|

(5) Improper nozzle installation. |

(5) Check for loose nozzles and reassemble the air cap and paint nozzle. |

Troubleshooting and Handling

Multiple faults may occur simultaneously.

The "Summary" column indicates the location of countermeasures by chapter and section. For example, "6- 5" refers to Chapter 6 (6. Installation), Section 5 [5. Assembly of Paint Nozzle].

|

Cause |

Countermeasure |

Summary |

|

(1) Insufficiently tightened nozzle. |

(1) Fully tighten the nozzle. |

6-7 |

|

(2) Damaged valve seat ring surface. |

(2) Replace the valve seat ring. |

- |

|

(3) Air entrained in the paint. |

(3) Inspect the paint supply system. |

9-1 |

|

(4) Extremely low paint output. |

(4) Increase the paint output or reduce the atomizing air pressure. |

9-1 |

|

(5) Loose mounting connector of the round nozzle (when using a round nozzle). |

(5) Tighten the round nozzle mounting connector with a socket wrench (Hex12). |

6-5 |

1. Reduced Paint Output

|

Cause |

Countermeasure |

Summary |

|

(1) Abnormality in the paint supply system. |

(1) Inspect the paint supply system such as the paint pump or paint regulator. |

2-1 |

|

(2) Cured paint or dust clogging the paint valve seat. |

(2) Remove and clean the paint valve seat. |

13-1 |

|

(3) Cured paint or dust adhesion on the paint nozzle. |

(3) Remove and clean the paint nozzle. |

6-5 |

1. Paint Leakage from Nozzle

|

Cause |

Countermeasure |

Summary |

|

(1) Clogging of the paint valve seat and plunger with paint lumps or dust. |

(1) Disassemble and clean the paint valve seat. |

13-1 |

|

(2) Wear or damage to the paint valve seat and plunger. |

(2) Replace the paint valve seat or plunger. |

13-1 |

|

(3) Relaxed spring or worn O- ring of the plunger assembly. |

(3) Replace the plunger assembly or O-ring. |

13-2 |

|

(4) Excessively high paint supply pressure. |

(4) Reduce the supply pressure. |

9-1 |

|

(5) Relaxed O-ring of the paint valve seat. |

(5) Replace the O-ring of the paint valve seat. |

13-1 |

1. Paint Leakage from Gun Extension

|

Cause |

Countermeasure |

Summary |

|

(1) Defective plunger seal gasket. |

(1) Remove the output adjustment knob and replace the seal gasket. |

13-2 |

|

(2) Insufficiently tightened or poorly sealed duct. |

(2) Replace the duct. |

13-2 |

1. Air Leakage from Nozzle After Trigger Reset

|

Cause |

Countermeasure |

Summary |

|

(1) Dust clogging the air valve seal. |

(1) Clean or replace the air valve and push rod. |

13-2 |

|

(2) Wear of the air valve and push rod. |

(2) Replace the air valve and push rod. |

13-2 |

|

(3) Relaxed spring. |

(3) Replace the spring. |

13-2 |

|

(4) Wear of the O-ring. |

(4) Replace the O-ring. |

13-2 |

1. Air Leakage from Air Valve Regulator

|

Cause |

Countermeasure |

Summary |

|

(1) Wear or damage of the O-ring. |

(1) Replace the O-ring. |

13-4 |

1. Sparks from Nozzle (Without Insulation Table)

|

Cause |

Countermeasure |

Summary |

|

(1) Damaged high-voltage generator. |

(1) Replace the high-voltage generator inside the gun. |

13-4 |

|

(2) Contamination inside the air cap. |

(2) Clean the inside of the air cap. |

13-3 |

1. rom Nozzle (With Insulation Table)

|

Cause |

Countermeasure |

Summary |

|

(1) Damaged high-voltage generator. |

(1) Replace the high-voltage generator inside the gun. |

13-3 |

|

(2) Use of low-resistance or metallic paint. |

(2) Lower the output voltage using the control box switch. |

9-2 |

1. Alarm Buzzer Activation on Control Box (Without Insulation Table)

|

Cause |

Countermeasure |

Summary |

|

(1) Paint adhesion on the gun extension. |

(1) Clean the gun extension. |

7 |

|

(2) Paint adhesion on the paint hose tip. |

(2) Clean the paint hose. |

7 |

|

(3) Moisture accumulation in the air path inside the gun extension. |

(3) Thoroughly drain moisture from the air path. Turn off the air supply and spray out the moisture in the air path. |

7 |

|

(4) Use of low-resistance or metallic paint. |

(4) Switch to low-resistance or metallic paint. |

8-2 |

|

(5) Paint leakage due to damaged plunger seal. |

(5) Replace the seal assembly, plunger sleeve, duct, and O- rings in the path. |

13-2 |

1. Alarm Buzzer Activation on Control Box (With Insulation Table)

|

Cause |

Countermeasure |

Summary |

|

(1) Paint adhesion on the gun extension. |

(1) Clean the gun extension. |

7 |

|

(2) Paint adhesion on the paint hose tip. |

(2) Clean the paint hose. |

7 |

|

(3) Moisture accumulation in the air path inside the gun extension. |

(3) Thoroughly drain moisture from the air path. |

7 |

|

(4) Insulation table too close to grounded objects. |

(4) Keep the insulation table at least 300mm away from grounded objects. |

7 |

|

(5) Paint adhesion on the insulation rod of the insulation table. |

(5) Clean the insulation rod. |

9-2 |

|

(6) Grounding of parts above the insulation rod of the insulation table. |

(6) Ensure no grounding of parts above the insulation rod. |

9-2 |

|

(7) Paint leakage due to damaged plunger seal. |

(7) Replace the seal assembly, plunger assembly, and O-rings in the path. |

9-2 |

Do not perform maintenance other than the methods specified in this operation manual. -31

Parts replacement and maintenance must be performed in the following order. Before proceeding, turn off the air supply to the spray gun and the controller power, drain the paint from the paint path, and clean it.

(Numbers in the text refer to the part numbers and item numbers in Chapter 5 "Exploded Views and Parts Lists".)

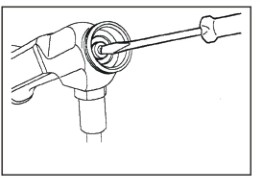

(1) Use a flathead screwdriver to remove the paint valve seat (33) at the tip of the extension tube. Perform assembly and removal of the paint valve seat while pulling the trigger. Use a flathead screwdriver.

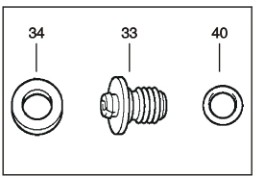

If the O-ring (40: 201-01-020) is damaged or swollen, replace it with a new one. If the seat gasket (34: 101-01-009) is damaged, replace it as well

(Installation of the valve seat ring: Insert the paint valve seat (33: 102-01-021) into the gun extension, place the valve seat ring, and tighten the nozzle.)

(1) Remove the hex socket bolt (46: 201-02-005) and sleeve (31: 102-01-003) to remove the trigger. Use a Hex3mm Allen wrench.

(2) Remove the connector (22: 102-01-016) and take out the three springs (19: 102-01-006, 20: 102-01-007, 21: 102-01-008). Use a Hex8mm wrench.

The threaded part of the connector is made of resin and may be easily cross-threaded. Exercise caution during installation.

(3) Press the gasket (15: 102-01-009) from the trigger opening and pull out the rod (12: 402-01-010) from the rear. Use needle-nose pliers. -33

(4) Loosen the hex nut (50: 201-03-001) and replace the air valve seat (18: 101-01-008), push rod (14: 102- 01-013), gasket (17: 101-01-004), plunger (11: 101-02-001), and O-ring (37: 201-01-008).

*For 1020 models, use part 11 (101-02-001).

(5) Insert an Allen wrench from the rear to remove the push rod bushing (101-01-013). If it cannot be pulled out due to dry paint adhesion, push it out from the paint valve seat side with an Allen wrench. Use a Hex5mm Allen wrench.

*For 1020 models, use part (101-01-013).

(When pushing out with an Allen wrench or replacing the gasket (9: 101-01-001), replace the duct as well.)

-34

(6) During assembly, adjust the length from the plunger tip to the rod end to 161~162mm. Use 5mm and 4mm wrenches.

(7) After installation, supply air to the paint hose and apply 2~3 drops of soapy water to the trigger opening to check for air leaks. Do not supply air to the atomizing air hose during this check (use only a small amount of soapy water; excessive soapy water may cause overcurrent).

If air leaks are detected, replace the push rod bushing (101-01-013) and gasket (101-01-001). -35

(1) Remove the hex socket bolts (47: 201-02-002), nut (54: 102-01-002), and hose support (55: 101-01- 007). Use a Hex3mm wrench.

(2) Remove the four hex socket bolts (201-02-002) and hook (29: 102-01-014). Use a Hex3mm Allen wrench.

(3) Gently pull the gun extension (5: 101-02-002) forward to remove it.

Pull the gun extension straight forward; do not twist or pull it at an angle, as this may damage the plunger and high-voltage generator.

(4) Remove the high-voltage generator (7: 104-01-001) from the gun extension and replace the two O-rings (44: 201-01-004). -36

(5) Connect the high-voltage generator terminals to the wires, paying attention to the wire colors to avoid incorrect connections.

(Green: GND; Red: RTN; Yellow: AC)

(6) During assembly of the high-voltage generator, rotate it two or three times to twist the wires slightly, then insert it into the gun body (1: 101-01-012) and assemble the gun barrel. Check that the gasket (35: 101-01-015) in the gun body is properly seated. Ensure the shoulder of the high-voltage generator is recessed behind the end face of the gun body before assembly. Replace the gasket (28: 101-01-017) each time the gun extension is disassembled.

(1) Disassemble the regulator.

(2) Replace the O-ring (49: 201-02-003) at the front of the air valve regulator.

If the O-ring is damaged, air leaking inside the spray gun will be discharged from the air valve regulator. Continued use in this condition may result in loss of high-voltage control; always replace the O-ring. -

Record all parts replacements, disassembly/cleaning, faults, and repairs here to facilitate future management. Please ensure this is done.

|

Machine Name |

Air Electrostatic Manual Spray Gun (1020) |

Purchase Date |

Month |

|

Maintenance Date |

Maintenance Location |

Summary |

Maintenance Date |

After the product leaves the factory, if there are defects in design, manufacturing, or labeling, our company will provide the following after-sales service to the original purchaser within one year from the date of purchase:

If parts have defects in design or manufacturing, please send them back to our company with prepaid shipping. After inspection and confirmation of our company's responsibility, we will cover the prepaid shipping costs, repair or replace the parts free of charge, and return them to the customer.

The following are not covered by the free after-sales service: faults caused by natural wear, corrosion, negligence, accidents, natural disasters, incorrect installation, improper use not in accordance with the operation manual, or unauthorized modifications without our company's approval.

Faults caused by using paint hoses, spray guns, or other accessories from other manufacturers not approved by our company will be subject to paid service. In such cases, the repair conditions and cost estimates for repairs or replacements will be provided clearly.

After-sales service for parts purchased externally by our company and used in the product will be in accordance with the manufacturer's warranty terms.

Our company's obligation ends upon replacing defective parts with new ones.

Our company shall not be liable for damages caused by improper use of the product or other reasons not attributable to our company.