Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: Block A No336, Changqing North Road Chanan Town . dongguan China

Hotline:+86-13622624429

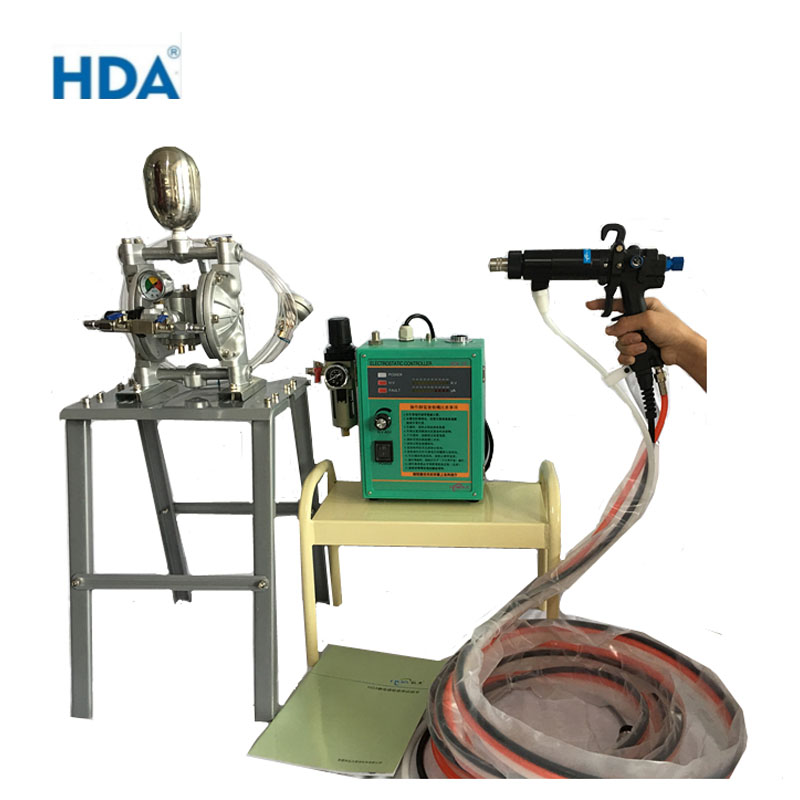

Why do liquid electrostatic spray guns need to undergo leakage, air leakage, and electrostatic alarm tests before the shipment?

These tests are based on the working principle of an electrostatic spray gun: it uses a high-voltage electrostatic field to charge paint particles negatively and adsorb them onto a grounded workpiece surface, but this process involves high voltage and gas/liquid transmission, with potential risks including electric shock, leakage, or fire

. The following points illustrate the necessity of each test:

Leakage test: The high-voltage system of the electrostatic spray gun may cause current leakage, such as through insulation materials or enclosures, which can endanger the safety of operators. Leakage testing verifies whether the leakage current of the equipment is within the safe limit under normal or faulty conditions, to avoid human electric shock or equipment damage

three

In the field of medical devices, similar tests (such as safety regulations) emphasize that any electrical equipment must undergo mandatory leakage current testing before leaving the factory to ensure user safety

Leakage test: The spraying system relies on pipeline tightness to transport paint and air. Leakage testing is conducted through pressure checks (such as injecting high-pressure gas/liquid and monitoring stability) to ensure that pipelines and joints are leak free. This can prevent paint waste, uneven spraying, or decreased system efficiency; Pipeline leaks may also introduce impurities that affect coating quality, and even lead to unstable high-voltage electric fields

four

Electrostatic alarm test: The high voltage environment of the electrostatic spray gun can easily cause sparks or malfunctions. The alarm system can monitor abnormalities in real time (such as voltage fluctuations or grounding failures) and trigger alarms through automatic tracking mechanisms. Test to ensure reliable alarm function, timely response to risks, and prevention of fire or explosion; Third party testing and verification of such systems are key to anti-static performance compliance

five

Before leaving the factory, comprehensive testing not only meets safety regulations (such as international electrical standards), but also enhances product durability and user trust. For example, high-quality spray guns can save over 20% of paint and reduce maintenance costs through rigorous testing

Neglecting these tests may result in recalls, accidents, or legal liabilities.