Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: Block A No336, Changqing North Road Chanan Town . dongguan China

Hotline:+86-13622624429

The key to solving the insulation problem of electrostatic spraying water-based paint lies in equipment modification and operational standards. Here is the specific plan:

1、Key points of equipment renovation

Insulation of paint supply system

The paint bucket should be placed on an insulated rack and kept at a distance of≥300mm from the surrounding grounding body.

The paint delivery pipeline and the high-pressure cable of the spraying tool need to be isolated and installed to avoid electrical breakdown.

Spray insulation treatment

Static spinning cups, spray guns, etc. need to be insulated, and the paint supply pipeline must not be grounded.

The distance between the spray nozzle and the surrounding ground should be≥250mm.

2、Operating standards

Current protection

Set the current protection value according to the spray nozzle brand (usually 200~300μA).

The recommended static voltage is≤75kV, balancing the cost of insulation materials with safety distance.

Safe operation

When adding or replacing paint, it is necessary to first cut off the static high-voltage power supply and fully discharge the equipment.

Operators should operate with bare hands and avoid wearing gloves or insulated shoes.

3、Coating characteristic adaptation

The resistance value of water-based paint is low (about 2-3kΩ), and insulation modification is needed to avoid static electricity leakage.

The recommended viscosity of the coating is around 20 seconds, and heating to 40℃can increase it to 30-40 seconds.

4、Common problem handling

Poor grounding of the workpiece: Measure the insulation resistance with a shaking table, and if it exceeds 1MΩ, clean the coating of the lifting equipment.

Spark discharge: Keep the distance between the spray gun electrode and the workpiece≥2.54cm/10000V.

Through the above measures, the insulation problem of electrostatic spraying of water-based paint can be effectively solved, ensuring stable operation of equipment and coating quality.

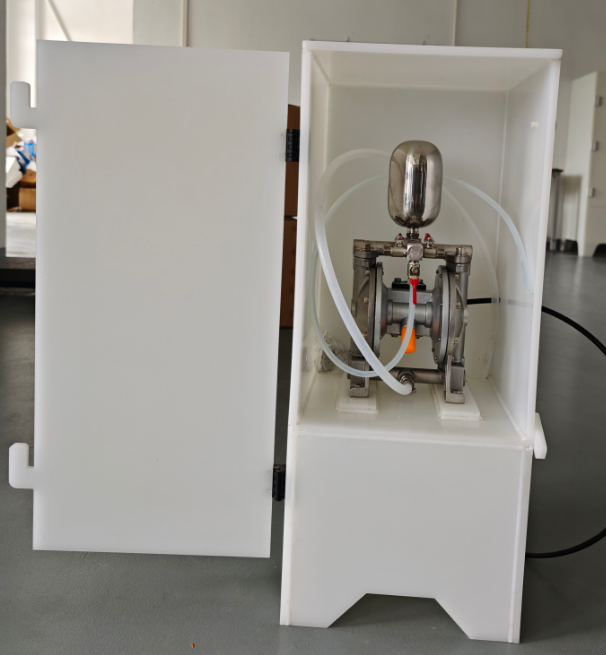

For example, Hongda's automatic spraying system is equipped with this wheel pump for paint supply, and the gear pump is designed to be off the ground with paint mixing system to achieve insulation effect,

1、Optimization of insulation performance

Insulation isolation technology: Through the insulation design of HDA-1020 spray gun, it effectively avoids static electricity leakage of water-based paint (with a resistance value of about 2-3kΩ), ensuring spraying stability.

Safety distance guarantee: The distance between the spray nozzle and the grounding object is≥250mm, and the paint supply pipeline is isolated from the high-voltage cable to reduce the risk of discharge.

2、Coating adaptability

Special design for water-based paint: HDA-1020 spray gun optimizes the conductive properties of water-based paint, achieving "water instead of oil" spraying and reducing VOC emissions by 60%.

Atomization and painting rate: Low pressure high atomization nozzle improves painting rate and saves paint; The spray amplitude adjustment valve is set on the left side for easy operation.

3、Operational safety

Circuit protection system: automatically shuts off, discharges, and beeps an alarm when abnormal voltage or current occurs, ensuring safe operation.

Easy to maintain parts: The spray gun components are designed in a modular manner, with low failure rates and low maintenance costs.

4、Customized services

Free trial spraying service: Provide a professional spraying laboratory to optimize equipment selection based on workpiece shape, coating type, and process requirements.

Industry adaptability: Suitable for 32 industries including home appliances, automotive parts, carbon fiber sports equipment, etc., to meet diverse needs.