Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: Block A No336, Changqing North Road Chanan Town . dongguan China

Hotline:+86-13622624429

Why is one electrostatic spray gun better than 10 air spray guns?

· The main advantage of electrostatic spray guns over air spray guns in industrial spraying is their efficient working principle based on electrostatic field force. By setting the spray gun as a negative electrode and grounding the workpiece to form a positive electrode, coating particles are adsorbed onto the surface to achieve efficient coverage. This design brings multiple performance improvements, making it possible for one electrostatic spray gun to replace multiple air spray guns:

· The utilization rate of coatings has been significantly improved: the painting rate of electrostatic spray guns can reach 45-75%,

· However, air spray guns usually only account for 25-35%; This means that electrostatic spray guns significantly reduce paint waste and save costs by over 30%.

· Significant improvement in spraying efficiency: The electrostatic spray gun utilizes electric field force to automatically adsorb paint onto multiple surfaces of the workpiece (including dead corners, sides, and backs), reducing the number of manual gun passes and spraying time. One device can complete the workload of multiple air spray guns.

· Better coating quality: Electrostatic spraying has finer atomization, uniform and full coating, strong adhesion, reduces defects such as orange peel, and higher surface smoothness and vividness.

Outstanding comprehensive economic benefits: reducing the need for spray booth maintenance, improving production speed, and saving labor and equipment costs in the long run. One electrostatic spray gun can produce output comparable to multiple air spray guns in efficient scenarios.

Therefore, the statement that 'one electrostatic spray gun is better than ten air spray guns' is mainly based on its comprehensive advantages of efficiency and savings, especially in large-scale production. However, it should be noted that electrostatic spray guns have specific requirements for the conductivity of workpieces (such as metals) and the electrostatic value of coatings, which limits their use in non-conductive materials (such as wood or plastic)

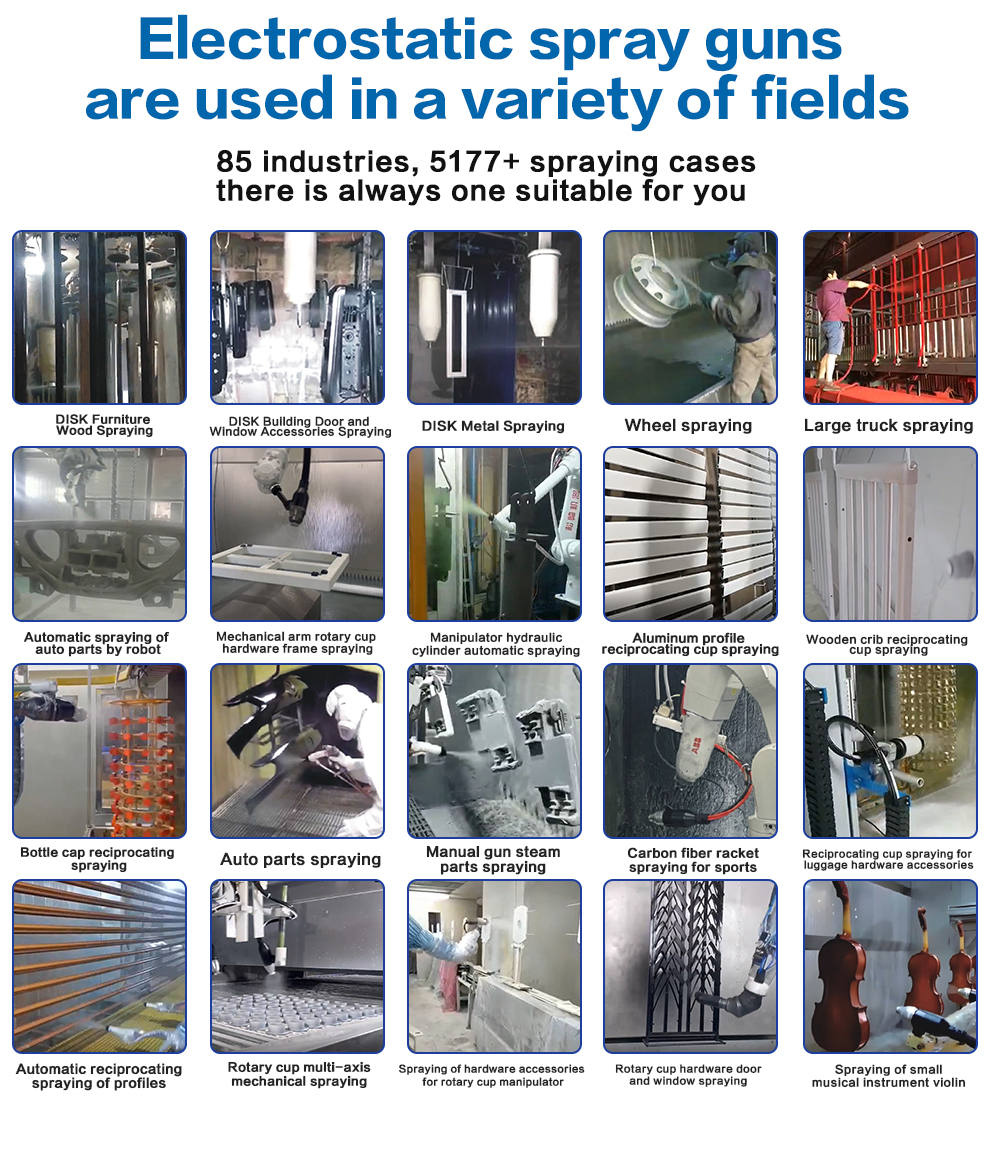

What materials are suitable for electrostatic spray guns?

The suitable materials for electrostatic spray guns are mainly concentrated on metal workpieces with good conductivity, and their principle relies on a high-voltage electrostatic field to orient the charged coating to the surface of grounded workpieces. The specific applicable scenarios are classified as follows:

1、 Core applicable materials (metal products)

Building and Industrial Metal Materials

Aluminum profiles, aluminum curtain walls, metal sheets, pipes, anti-theft doors and other building materials

Large metal structural components (such as train carriages, mechanical casings)

Precision Hardware and Components

Automotive parts (wheels, body parts), hydraulic mechanical components

Bathroom hardware (faucets, metal brackets), musical instrument accessories, household appliance casings (metal parts)

Chassis, electronic device metal frame

2、 Limitations Explanation

Non conductive materials require pre-treatment: Insulation materials such as wood and plastic cannot directly form an electrostatic field and need to be pre coated with conductive primer or surface metalization treatment

Complex structural challenges: Complex geometric shapes such as deep holes and multiple angles may result in uneven electric field distribution, requiring optimization coverage with technologies such as rotary cup spray guns

Key principle support

The electrostatic spray gun uses an 80-90kV high-voltage electrostatic field to negatively charge the coating particles, and the workpiece is grounded to form a positive electrode, achieving efficient adsorption. The natural conductivity of metals makes them an i