If distinguishing whether a liquid electrostatic spray gun is good or not

Spray uniformity and coating quality

Case HDA-1020 manual electrostatic spray gun reduces paint return by extending the gun body design, and improves atomization fineness by 30%.

Core component materials and processes

High voltage generator

The output voltage needs to be stable between 20-80KV

Gun nozzle and needle assembly

Material: tungsten steel or ceramic gun needles (corrosion-resistant and wear-resistant), stainless steel nozzles (with a lifespan of>5000 hours) are standard.

Concentricity: Needle nozzle gap ≤ 0.01mm, poor quality spray guns may cause rough atomization particles due to large tolerances.

Gun body design and lightweight design

High strength composite material gun body (weight<500g, such as HDA manual gun)+ergonomic handle, greatly reducing operational fatigue

Security protection mechanism

Static constant current protection: automatic power-off in case of overload (such as the buzzer alarm of HM-09)

International brands: Graco (high voltage isolation technology), Wagner (precision atomization control);

Chinese brand: HDA Electrostatic spray gun (with built-in high-voltage design)

After sales and cost control

Spray nozzle atomization accuracy: Circular nozzles (concentrated atomization) and fan-shaped nozzles (large coverage area) need to support quick replacement and adapt to different workpieces (such as complex corners or large-area planes).

Case HDA-1020 manual electrostatic spray gun reduces paint return by extending the gun body design, and improves atomization fineness by 30%.

Core component materials and processes

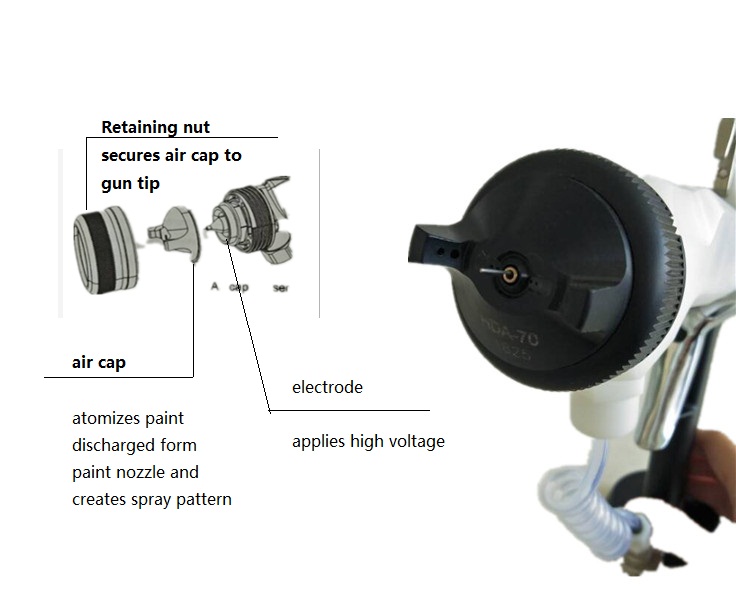

High voltage generator

The output voltage needs to be stable between 20-80KV

Gun nozzle and needle assembly

Material: tungsten steel or ceramic gun needles (corrosion-resistant and wear-resistant), stainless steel nozzles (with a lifespan of>5000 hours) are standard.

Concentricity: Needle nozzle gap ≤ 0.01mm, poor quality spray guns may cause rough atomization particles due to large tolerances.

Gun body design and lightweight design

High strength composite material gun body (weight<500g, such as HDA manual gun)+ergonomic handle, greatly reducing operational fatigue

Security protection mechanism

Static constant current protection: automatic power-off in case of overload (such as the buzzer alarm of HM-09)

Brand and Service Guarantee

Brand technology accumulationInternational brands: Graco (high voltage isolation technology), Wagner (precision atomization control);

Chinese brand: HDA Electrostatic spray gun (with built-in high-voltage design)

After sales and cost control

High quality spray guns have a failure rate of less than 1% per year, and provide a 1-year warranty for core components (such as HDA-1020 modular parts replacement design)

Previous:Is already the first one

BACK

BACK HDA HOME

HDA HOME Navbar

Navbar