- wine bottles spraying

- Carbon fiber sporting goo

- Burglarproof door industr

- Door and window accessori

- Home appliance / kitchenw

- Auto parts spraying

- Construction machinery sp

- Wood products, furniture

- Plating,protection,etc sp

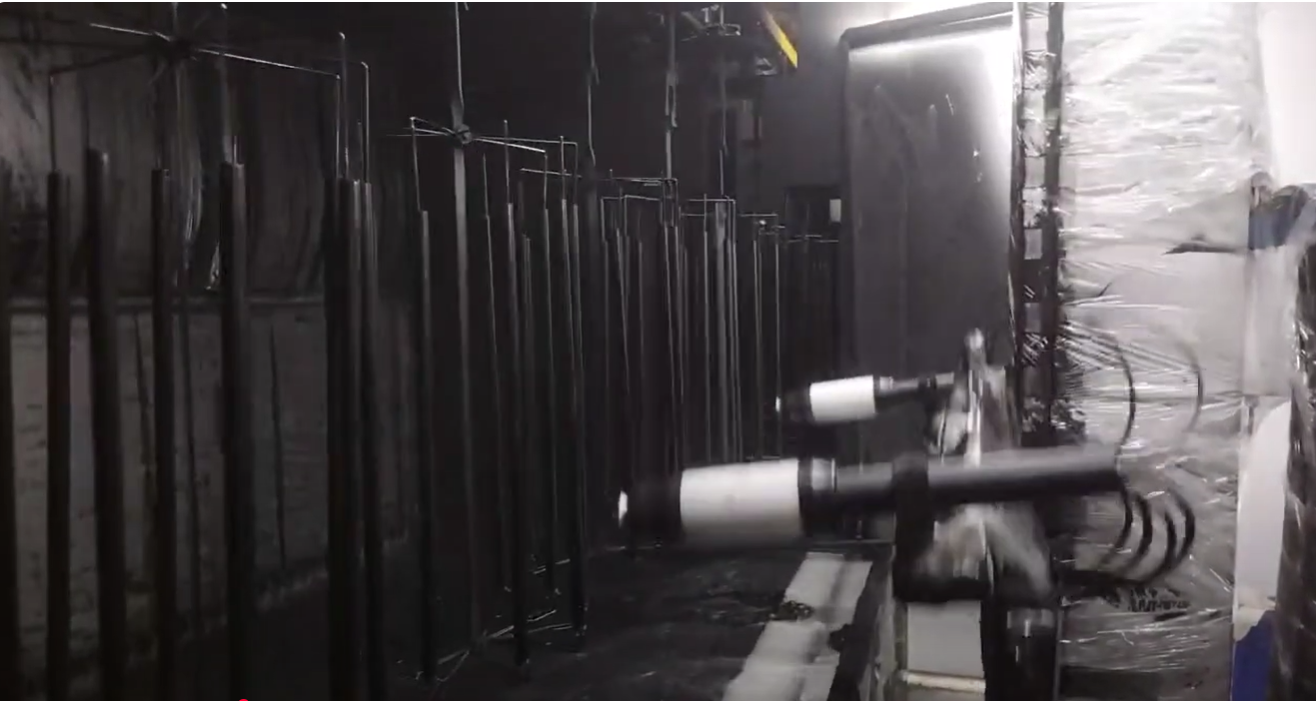

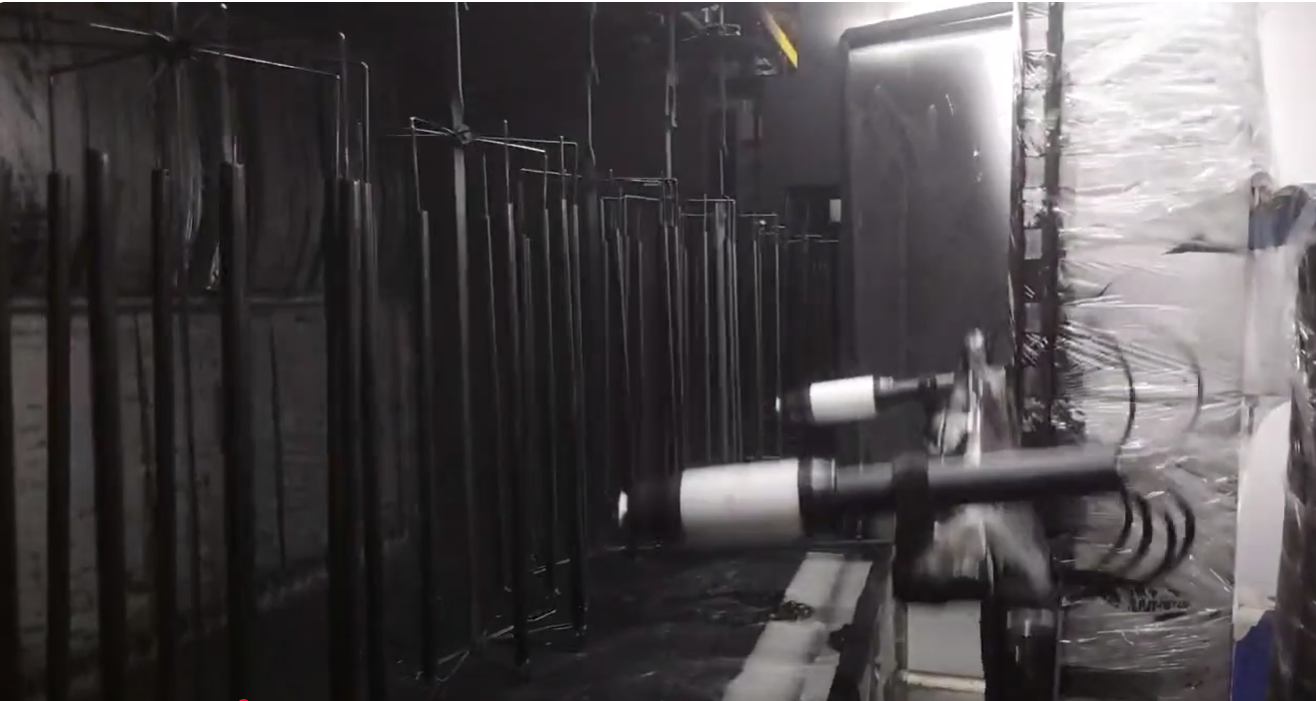

Household applicances Bathroom towel rack HDA spray bell Reciprocating machine automatic spraying

2025.08.20

Household applicances Bathroom towel rack HDA spray bell Reciprocating machine automatic spraying

Principle of electrostatic Rotating bell spraying technology

High speed centrifugal atomization

The spraying equipment is driven by compressed air to rotate the rotary cup at high speed (up to 50000rpm)

Under the action of centrifugal force, the coating is atomized into fine particles of 50-100 microns, forming a uniform and delicate paint film, significantly improving surface smoothness and glossiness

Electrostatic adsorption enhances efficiency

Rotating cup with negative high voltage (typical value -60kV)

The coated workpiece is positively charged and guided by a strong electric field to accurately adhere the paint mist to the surface of the workpiece. Especially for complex curved surfaces (such as towel rack bends and edges), it can achieve seamless coverage and reduce paint waste

core advantages in the production of bathroom towel racks

Improvement of coating quality

Fine atomized particles, high smoothness of paint film, effectively avoiding the orange peel phenomenon of traditional spraying

Electrostatic adsorption evenly covers the concave structure (such as the hook connection) of the coating, enhancing its anti-corrosion performance

Environmental protection and cost-effectiveness

The painting rate can reach over 80% (30% higher than traditional spraying), reducing paint waste and solvent evaporation (lowering VOC emissions)

Suitable for water-based coatings, in line with environmental trends

Adapt to automated production

Can be integrated into robot or reciprocating machine automatic spraying systems to achieve large-scale and efficient operation of bathroom hardware, such as the Hongda HDA-605 high speed electrostatic rotating bell spray system specifically for automated production lines

Key process parameter control

Typical Value Range for Parameter Function Explanation

The rotational speed of the rotary cup affects the atomization fineness: the higher the rotational speed, the finer the paint particles (too high may cause dry spraying)

Color paint: medium low speed; Clear varnish: high-speed

Paint flow control requires adjusting the thickness of the paint film according to the shape of the workpiece (flat>angular) 0-300cc/min Typical application scenarios

Material adaptation: mainstream towel rack substrates such as space aluminum and carbon steel, with strong coating adhesion

Function expansion: Suitable for surface treatment of basic to high-end intelligent models (such as heated towel racks), balancing aesthetics and durability

Note: This technology requires professional equipment support (such as spray painting systems from brands like Crown, Hongda, etc.)

And it is necessary to optimize the parameter combination (flow rate/speed/voltage) to match the characteristics of different coatings

Previous:Robot Spraying System HDA Lqiuid Paint Electrostatic Industrial spray coating machine

Next:lighting parts by Smart liquid electrostatic rotatin bell HDA-603

BACK

BACK HDA HOME

HDA HOME Navbar

Navbar

Other Project

Other Project