Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: Block A No336, Changqing North Road Chanan Town . dongguan China

Hotline:+86-13622624429

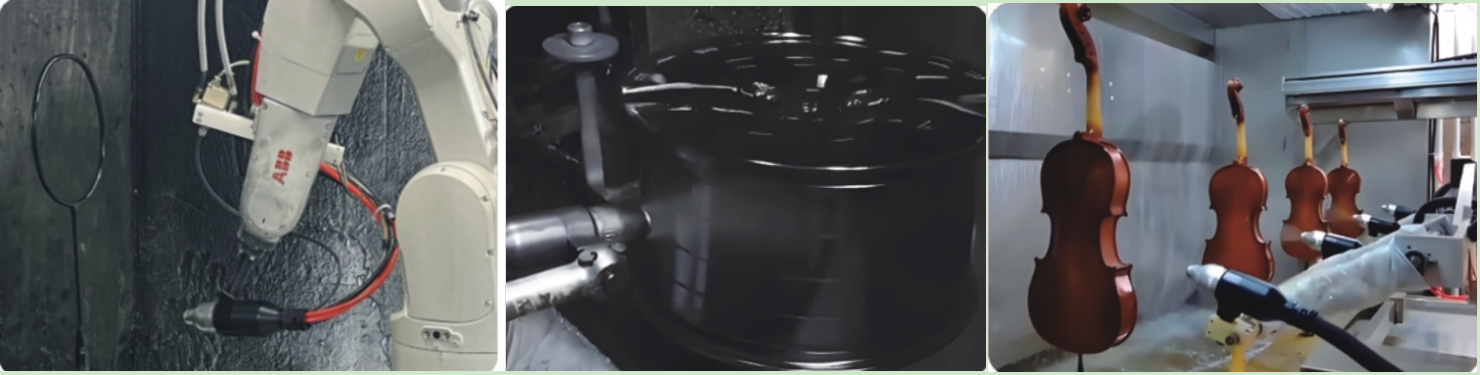

Yes, the High-Speed Electrostatic Rotating Bell Spray System is highly suitable for automotive wheel hub coating.

This technology combines the dual advantages of high-speed rotating atomization and electrostatic adsorption, effectively addressing the coating challenges posed by complex geometric shapes such as wheel hubs

Efficient Atomization and Uniform Coverage: The rotating cup centrifuges the paint at extremely high speeds (up to tens of thousands of revolutions per minute), breaking it into extremely fine particles. Combined with a high-voltage static electric field (typically 100,000 volts DC), the charged paint particles are directed to adhere to the grounded hub surface under electrostatic force. This ensures a uniform paint film, particularly achieving perfect coverage of complex, hard-to-reach areas such as the inner sides of wheel spokes and the back of the rim, eliminating spray dead zones.

High coating efficiency and eco-friendly energy savings: Electrostatic adsorption significantly enhances the transfer efficiency of coatings, reducing splatter and waste. Compared to traditional air spraying, it saves a substantial amount of paint while lowering VOC (volatile organic compound) emissions, better aligning with modern green manufacturing requirements.

Excellent Paint Film Quality: By precisely controlling parameters such as the rotation speed of the rotary cup, paint flow rate, forming air, and voltage, a smooth, flat, and highly glossy paint film can be achieved, meeting the high standards for both aesthetics and durability required by automotive wheels.

Automation and Intelligence: Modern systems typically integrate PLC control systems paired with HDA 603 smart high-speed electrostatic rotating bell spray guns, enabling automatic color change for different hub models, process parameter database management, real-time equipment monitoring, and self-diagnostic fault detection, meeting the demands of flexible and mixed production lines.

The HDA 603 smart electrostatic speed rotating bell spray system:

Good performance

120000Rpm high speed rotating by the air turbine bearing with more stable and reliable in surface coating.

High spray quality

Good atomization low pressure forming,flexible movement good to apply multi-axis fixed with as 0.5kgs weight of the bell gun.

Save cost

Improves painting rate around 85%, to achieve VOC reduces to save cost and environment protections.

Flexible application

Dexterous as the 0.5kg bell gun body weight flexible for multi-axis coating robot apply and for reciprocation machine for the auto spraying.

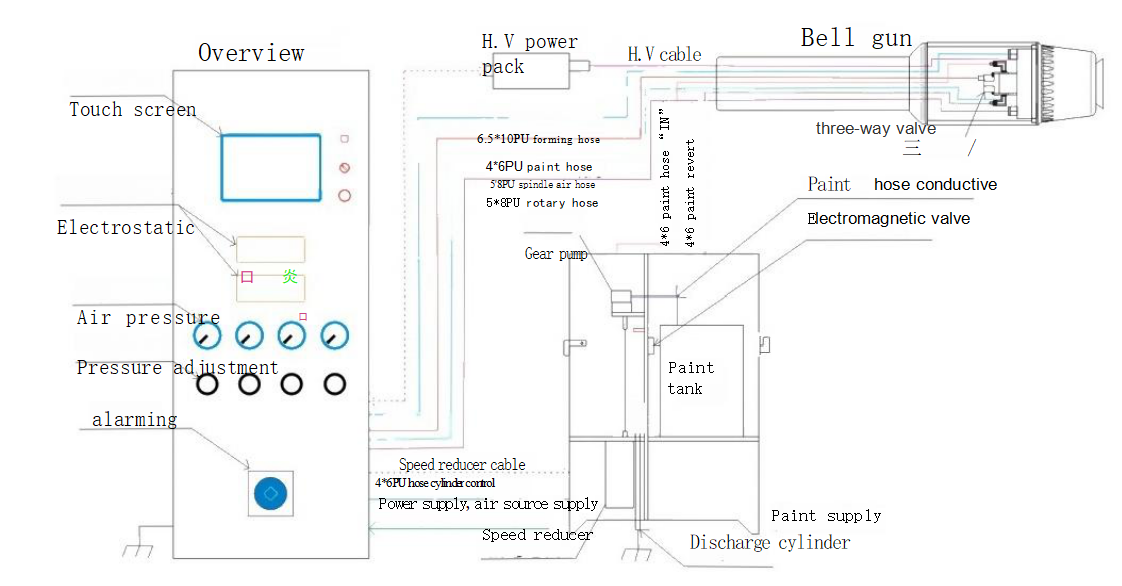

connection diagram

Is the high speed electrostatic rotating bell spray system only for car wheel coating?

High speed electrostatic rotating bell spray system is not limited to the spraying of automobile wheels. This technology is mainly applied in the field of automobile manufacturing, used for efficient and high-quality paint spraying of large metal parts such as the body, doors, and engine hood. Its core advantage lies in significantly improving paint transfer efficiency, reducing paint mist waste, and environmental pollution through electrostatic adsorption and rotary atomization

Although car wheels are sometimes sprayed with this system, it is just one of its many application scenarios. This technology is also widely used in other industrial fields, such as:

Spray coating of household appliance casings (such as refrigerators, washing machines)

Protective paint coating for industrial equipment and metal structural components

Precision coatings for aerospace components

Automated spraying of large furniture and metal products