Contact person: Ms Croesus

0769-81885105

Phone: +86 13622624429

E-mail: hda-sl01@hongdapt.com

Skype: hongdapt@outlook.com

QQ: 1550167687

Factory: Block A No336, Changqing North Road Chanan Town . dongguan China

Hotline:+86-13622624429

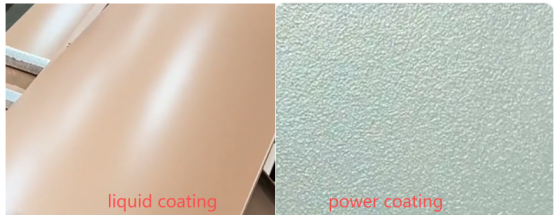

The main differences between powder coating and liquid coating in the painting of automotive parts are as follows:

1. Process and raw materials

Powder coating: Using solid powder coatings, they are electrostatically adsorbed onto the surface of the workpiece, and then melted and solidified through high-temperature baking to form a uniform coating.

Liquid spraying: Using liquid paint or solvent-based coating, it is dispersed into droplets through compressed air and directly sprayed onto the surface of the workpiece, which is then naturally dried or low-temperature baked to form a film.

II. Coating Performance

Powder coating: The coating is thick and uniform, with strong adhesion, good corrosion resistance, and good aging resistance, suitable for outdoor and industrial environments.

Liquid spraying: The coating thickness is relatively thin, with weaker durability, but it offers greater flexibility in color expression and surface texture.

III. Environmental friendliness

Powder coating: It rarely uses organic solvents, has a high powder recovery rate, and emits extremely low VOC emissions, making it more environmentally friendly.

Liquid spraying: It contains volatile organic compounds, thus posing higher requirements on the construction environment and personnel health.

IV. Cost and Maintenance

Powder coating: The initial cost is relatively high, but the long-term maintenance frequency is low, and the overall operating cost may be more economical.

Liquid spraying: The initial cost is relatively low, but it is prone to aging and requires regular touch-ups and refurbishments.

V. Applicable Scenarios

Powder coating: suitable for industrial products with high requirements for coating thickness and uniformity, such as mechanical parts, electrical appliance housings, automotive parts, etc.

Liquid spraying: suitable for temporary projects, indoor low-standard projects, or coatings requiring complex colors and effects.

What advantages does the Hongda electrostatic spray gun offer?

The core advantage of Hongda electrostatic spray gun lies in its full product coverage, technological innovation and patent support, as well as its strong customization service capabilities, which can meet the painting needs of various industries such as automotive parts.

1. Full product coverage

Hongda provides a full range of electrostatic spray guns, from manual to automatic, including manual electrostatic spray gun (HDA-1020), automatic electrostatic spray gun (HDA-90A), rotary cup electrostatic spray gun (HDA-605/603T), water-based paint electrostatic spray gun (HDA-360), and robotic electrostatic spray gun (HDA-603Y), which are suitable for various installation methods such as fixed, reciprocating machines, and robots.

II. Technological Innovation and Patent Support

Hongda holds multiple utility model and design patents, including air bearing turbo motors and low-rebound atomization systems. Its rotary cup can reach a maximum speed of 120,000 rpm (no load), with a paint transfer efficiency exceeding 85%, which is 10%-15% higher than the industry average.

III. Customized service capability

Hongda is equipped with a professional spraying laboratory, which supports free trial spraying. Based on the customer's workpiece shape, paint type (water-based/solvent-based), and process requirements, we can optimize equipment selection and provide customized solutions. For example, the rotary cup electrostatic spray gun customized for bicycle carbon fiber frames reduces paint loss by 25% and improves surface smoothness to industry Grade A standards.

And the spraying performance of HDA-605 is as follows:

The HDA-605 rotary cup electrostatic spray gun excels in the painting of automotive parts, particularly in spraying complex curved surfaces. Its core advantages are as follows:

1. Rotating speed of the spinning cup and atomization effect

70,000rpm ultra-high speed rotation: By utilizing centrifugal force, the paint is atomized into micron-sized particles, achieving a finer atomization compared to ordinary spray guns, and improving the uniformity of the coating by 30%.

Electrostatic attraction and retention: Negatively charged paint particles are attracted to the positive electrode of the workpiece, increasing the coverage rate of edges and corners from 70% to 95%, reducing the risk of missed spraying.

II. Adapt to complex surfaces

Specialized design for automotive parts: Optimized for irregular workpieces such as car bodies and carbon fiber frames, the integrated solution of spin cup and robot (HDA-603Y) can cover over 95% of the edges and corners.

Case verification: Actual testing of the Xidesheng bicycle carbon fiber frame shows that its surface smoothness meets the industry's Grade A standard, and paint loss has been reduced by 25%.

III. Cost and efficiency advantages

Price competitiveness: The price of automatic electrostatic spray guns is 25%-35% lower than that of imported brands, but the paint saving rate is on par with imports (20-30%).

Quick service response: With service points established in 8 provinces nationwide, we can arrive at the scene within 24 hours, avoiding production line downtime.

IV. Technical Details

·Rotating cup edge corona discharge: After the paint particles are negatively charged, they are adsorbed by the workpiece, forming a uniform coating.

Centrifugal force and electric field force collaborate: The rotational speed of the rotary cup is matched with a high-voltage electric field to achieve efficient atomization and adsorption.